The design process for a high performance home in the forests of Southern Vermont

Process and Engagement - upping my game

A Better Way to Build

We are starting a new Bluetime Collaborative project here in the Brattleboro area. This will be a High Performance house that will provide the chosen team including myself and the builder the opportunity to refine the integrated process that goes with building a HPH. We don’t know yet if this project will be built toward any certification such as Passive House or Efficiency Vermont’s High Performance Home program. That question will be addressed early on in the design process. I reworked my contract quite a bit to set up and guide the process better than a standard contract does. This includes fleshing out the design process, what to expect and when, expected meetings along with the purpose and goals of those meetings and finally, guidance with selecting the right contractor for the job at the start of the project – meaning at the start of design.

I am fortunate to live and practice in an area with an impressively large number of excellent builders with a high level of interest and enthusiasm for building science and green building and training in Passive House and high performance building. I have been finding that I can’t or rather, shouldn't, as an architect, design and detail a HPH without the full partnership of the people who will be doing the actual building. I can’t draw up a set of plans and send them out to bid. There are many conversations to have during the design process with the builder and a high level of builder competency and knowledge is required.

The process of designing and building a High Performance Home requires a level of integration between architect and builder that is uncommon. In the past I have followed a more traditional approach, working with the client to develop a design then taking it to one or more builders to price and build. This is the normal way things are done and many builders and architects prefer this approach. I have decided however that to provide the level of service and quality of product that I want to be known for, a truly integrated and refined process where the builder is retained at the very beginning, provides expertise, guidance, cost-benefit analysis + research support from the very beginning of design is necessary. And I provide similar through construction.

The result can be much more time and resource efficient process, a more refined and well designed project, and overall, a higher level of control and accountability for the builder, the architect and most importantly, the client.

For this project, I introduced my clients to three such general contracting firms and helped them interview all three. The first meeting was with Josh and Gero of Mindel and Morse Builders – a firm that have worked a lot with. I was a carpenter with them in the late nineties after architecture school. The second meeting was almost immediately after that with Scott and Gabe of Mathes/Hulme. I had done the Brattleboro Tiny house with them several years ago when they were just getting started on their own and we have been looking for a project to do together ever since. Later in the day we met with Chad of Vermont Natural Homes (who built the Greenfield house) at his own straw bale home complete with an amazing spread of hors de vors (thanks Carly!) Wish I had gotten a pic of that.

All three firms are super-professional and very supportive of each other. There is an impressive culture of support among many local builders locally with a monthly building science group that supports continuing education and discussion. Firms often help each other out with manpower and expertise. This project can provide an excellent case study and learning opportunity for the local building community.

Over the next week, the clients were further wined and dined by the builders with house tours and the clients were starting to realize not only that they were in good hands but that they had a really difficult decision to make in choosing which builder to hire.

So now that I have put some serious pressure on myself (and the builder) to do an awesome job, I will reveal that the clients have chosen Mathes/Hulme who are now busy writing up a pre-construction agreement which will be a further definition of their role in the process that I introduced in my own proposal. I haven’t had a conversation with the clients yet about what tipped the scales toward Mathes Hulme. I tried to remain very neutral during the interviews which was rather easy as I was just pleased with the opportunity to work with any of the firms.

I will be meeting this week with Gabe Hulme and Mel Baiser of Helm Construction Solutions, a construction management firm that both Mathes/Hulme and Vermont Natural Homes use. We will discuss first steps, who will be doing what and when – process and scheduling. We will discuss how communications will be handled (we might give Slack a try) and generally mapping out the next few months. I have been sketching - schemes, sections, details etc to start that conversation with the builder before I refine it a bit and present to the client.

Stay Tuned!

Here is an article about High Performance Homes in ISSUES in Science and Technology

New Video features the Greenfield House team

The Main Team for the Greenfield house put together a short video about the house and the process of build an home with an integrated team which is pretty much necessary to do a high performance home. This video briefly explains a bit about what that means. The key players are Chad of Vermont Natural Homes, Mel of Helm Construction Solutions and myself, Bob Swinburne of Robert Swinburne Architect, LLC and Bluetime Collaborative, which represents the bringing together of key players in a collaborative team which is how I like best to work. Grady Smith of Grayson Digital did the filming and video production

Here are a few other videos that I have been featured in. The first features the Fern House and has been viewed over 28k times by now. The second is called "Living Small - Tiny House Documentary and has been viewed over 50k times

Greenfield project update

I have a lot of photos from the Greenfield project. I am spending a fair amount of time on site working out details with the builder. I strongly feel that this is the way it should be. Things never translate perfectly from paper to built form no matter how much detail and specificity I put into a set of construction documents and on this project, I am spending much time on site figuring things out and detailing to a higher level. I think Chad, the builder, appreciates this process and I'm finding that it hearkens back to my pre-architect design build days. I hope to do more projects with this level of involvement in the future. I really think that this is "the way to go" here are lots of photos. Note the local wood use: Cherry stair treads with "live" edge, local maple flooring downstairs and pine upstairs, Vermont slate, and a wall sheathed with weathered pine off my own land.

Greenfield House project update

I spent part of Sunday painting at the Greenfield project with the builder Chad of Vermont Natural Homes. The all white primer that drywallers left us with was rather intense in the bright winter sun. The main bedroom upstairs which faces south was almost too bright to tolerate. It was good to spend much of the day there on a sunny day to better understand the light and to see how things will photograph when all is said and done. The color we used is a light blueish gray and it really had a soothing effect on the main room. I hope it will feel warm at night under artificial light as well. I am a bit concerned about this room as it had so much going on in terms of different materials on different surfaces. It was nice to spend the day talking with Chad about design and business and such. I don’t often get to interact on that level with the builders. There is a lot going on in this house that will help me learn and get better as an architect and help Chad get better as a builder. Plus the part where it is shaping up to be stunningly beautiful.

We tried a different construction method for this project than plain old double stud walls. There is potential in this method – (see previous post) but I don’t think we gained as much as we hoped in terms of air tightness and ease of construction. There are some Passive House builders using this method to hit ridiculously low cost per square foot numbers and it has numerous other advantages. I look forward to improving the detailing next time around. Double stud construction (used on the Ames Hill Project shown below) is the local standard here in Southeastern Vermont. The cost/benefit ratio is very high and local “green” builders are very familiar with it and prefer to build this way. Some local builders are also starting to advocate using locally milled boards as sheathing rather than OSB and plywood as well. I asked around (sent out a formal questionnaire even) and most think the cost difference is negligible.

We also had issues with the trusses on the Greenfield project. Maybe we just had bad luck but it seems that whenever I’ve tried to specify trusses to save money, they come through just imperfect enough to cause problems that need to be solved in the field.

I detailed lots of things both interior and exterior in such a way that they can be filled in later but don’t interfere with occupancy permit and impression of completeness. The sheetrock around the deep set windows for instance, costs more on the drywaller’s bill but when they leave, the window is essentially trimmed out. Done. We can add a sill later. Perhaps even just laying some slate tiles on the window sill. I have found that using wood trim on deep windows looks too...heavy and complicated. There are more cool and experimental things happening at this project as well which I will detail in a later blog post as they happen.

The stairs aren't in yet so I did some quick and dirty photoshopping:

The stairs aren't in yet so I did some quick and dirty photoshopping:

On most (all?) projects there is a level of design that is in the earlier, preconstruction drawings and models that I find really hard to convey to builders and clients and thus gets edited out of the final constructed project. Things that often look unnecessary on paper and I sound silly trying to explain but, the older and more experienced I get, the more I understand how important these things are. Once in a while I have a client who trusts me enough to let me do what I do to a greater extent. I suspect I have been luckier than most architects in that regard. I am so often trying to use space, light (and dark), flow, texture, detail, color etc. to shape and affect emotion and state of mind for my clients and I hope that long after I’m gone that will be a big and recognized part of my legacy.

This project and the Ames Hill Project have been opportunities to work with - and see how to work with - a full-on construction management firm – Helm Construction Solutions. This is part of trying to reach a higher level of service as an architect (it’s a hard thing to do as a sole proprietor) as well as re-write how projects happen locally. I have lots of cost and pricing information gathered on my own over the years that I can use for rough estimating purposes but what Helm does involves knowing the cost of things much more accurately earlier in the process. I have found few builders who can really do this well. It tends to be a level of service one would expect of a larger firm with a dedicated staff (back at the office) for this aspect of construction. It’s very much about managing expectations, communications, process, accountability and smoothing the tumultuous process of building as much as possible.

I filled out some of the Bluetime Collaborative section of my website finally – check it out from the top menu.

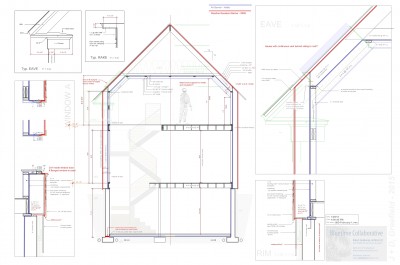

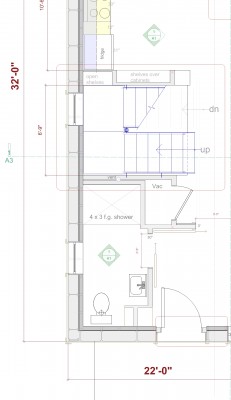

New and Improved plan set structure

I'm trying out something new: a smaller scale simplified plan with all major reference information on the front cover so the contractor has one place to find all sections, details and locate windows and doors.

The floor plan gets broken into three 1/2" scale sheets later in the set. I learned that from looking at a set of very complete drawings from a big-time NY firm that a contractor friend was building from. 1/4" per foot drawings are more traditional but 1/2" scale (twice as big) is very relevant to modern high efficiency buildings where framing is much more relevant to windows and doors as well as being easier to understand air sealing details. There are also places where I need to show actual framing in plan.

I also try to get relevant section details on the same sheets as the overall sections where possible. I learned this from my days as a carpenter as well as through feedback from builders over the years.

Hemlock - Open Gap Rain Screen Siding

My use of eastern hemlock as a siding material has been generating interest. Hemlock is a common wood in Vermont but doesn’t get used a lot except in barns and outbuildings and sometimes for timber frames. My summer job during high school involved working in a small sawmill. We sometimes cut hemlock and I found the wood beautiful, but heavy. One summer, we cut some hemlock for a bridge. Fast forward um… lots of years and I ordered a bunch of hemlock for framing and decking when I built my barn. I learned a bit about how to work with hemlock, how it ages and weathers and I started thinking about how I could use it in my own work. I try to source materials as locally as possible and design within local builder's abilities and interests - which is easy to do here where builders get together monthly to discuss building science related issues

In rural New England, buildings are often sided with pine siding in a vertical shiplap form – and often unfinished. It tends to develop a black mold that is relatively harmless but can be ugly. I found that hemlock is more resistant to this mold. It’s also harder and more rot resistant. It is nowhere near as rot resistant as cedar, a more common siding material however.

White pine siding on my own barn

A brief on open rainscreen siding: Good architect and builders are installing siding with a vented airspace between the siding and weather resistant barrier (WRB). This allows any moisture that gets behind the siding to dry out before it does damage. Modern materials (a better WRB) and the venting detail allow us to use different materials and different details for the siding itself. I have commonly seen the open gapped rainscreen detail used with ipe boards but Ipe is a tropical hardwood related to mahogany. Cement based boards are also used commonly but cement has fairly high embodied energy. Both of these are not locally sourced materials. The gap in the siding also reveals a view of the WRB (depending on the size of the gap) This means that damaging UV rays are also reaching the WRB. And bugs. Thus the need for a better (and black) WRB. There are several on the market designed for this. Both projects shown here use Mento and tapes from Foursevenfive.com

It occurred to me that I could use narrow hemlock boards from local mills to create a very elegant (I hoped) rainscreen siding detail. It would use local and relatively inexpensive materials, it wouldn’t need paint or stain, installation could be simpler and faster if I got the details right, and if I installed it horizontally, the lowest courses could easily be replaced if the siding degraded due to splashback and snow banks. The damaged siding would not present a disposal concern – just toss it in the bushes and it becomes habitat for red backed salamanders. I was lucky to have a client with a taste for modernism allow me to try my ideas out on his home. The results were rather spectacular and gave me a sense of the potential. Now I am doing my second project with hemlock siding. The builders for this project (Webster Construction of Marlboro, Vermont) are quite familiar with good building science and modern products and methods. They saw the potential and were happy to give it a try plus they were able to improve my detailing in several ways which I can then incorporate into drawings and specifications for the next time around.

The hemlock turns silvery gray within a year. The narrow boards create a woven, fabric-like aesthetic.

The hemlock is installed "green" with deck screws. This siding is all 1x3 so gaps will be quite small as the wood dries. Fiberglass bugscreen is installed directly behind the siding. strapping can be regular 1x3 strapping although coravent makes an excellent product for this purpose and should at least be used on any strapping set horizontally such as over and under windows.

This is the corner trim detail the builder came up with and I really like. One side runs long and is cut after installation. The other side is held back for a crisp reveal - very architecty! Of note: the deck is white oak (local) and the post is European Larch which is from a harvest of a Vermont tree farm. European larch is used in Europe as a durable siding material that needs no treatment.

detailing around windows is super simple. On the first house I used metal panels (installed by the roofer) to accentuate the windows and wrap corners. Here it is about as simple as it gets.

High Performance Window Installation - Part 1

Today's post is about windows. Specifically installing high end windows. Most American architects and builders don't have to read this or worry about this. Nothing to see here... move along. For those of us working on a higher level, however, windows and window installation are hot topics. I have to tailor the construction documents according to the windows chosen. This is a fair amount of work I didn't have to do in the past. The actual installation is now on my plate as something I need to be on site for as the architect. I was on-site last week at the Greenfield project and took some photos. Chad (the builder - Vermont Natural Homes) and I had much fun working out the installation details for the Klearwall windows chosen for this project. Our goal is to simplify the installation details to the greatest extent possible, minimize the possibility of water infiltration and create a system that can easily be monitored over the years for durability. We use tapes and weather barriers from foursevenfive.com to accomplish this. Calk has no place on the exterior of a modern high performance home (that is SO nineties) Our trim detail (subject for a future blog post) is designed so that we could easily remove the casing around the exterior of the window to inspect the taped joints.

We start with a fairly traditional clapboard at the window opening to provide a bit of pitch.

ys

ys

Then we use Extoseal to provide a sill pan. IF any of you have ever used Bituthene for the is purpose, I feel for you. I really do. But don't ever do it again. There is a better way.

Check how the Extoseal turns the corner. Note also the integrated exterior sill. Different manufacturers handle this in different ways. I think the Klearwall way is less elegant than some.

The next trick is to use Tescon Profil to tape over that annoying joint at the junction between the sill and the window frame. after several tries we came up with an excellent and easily teachable/repeatable solution. This all gets hidden with trim so we prioritize "good" over "neat"

The up and around part is relatively easy. We inset the window in the opening to make it so. This allows up to uncouple the head flashing from the window flashing in a simplified manner. The head flashing detail will be covered in a later blog post (along with the trim)

Then, happy with what we had figured out for the windows, we turned our attention to the door. And I wrote all over everything. Because I'm an architect.

Progress Photos

Here are some progress photos on a current project which should interest those interested in building science. The AH project is under construction fairly close to my own home so I can get over there frequently. This will be a fairly modern house with large windows, double stud cellulose filled walls, a high level of air sealing and an amazing three season porch using the Kent Webster's (the builder) most excellent system of removable panels. The most interesting thing in these photos for many readers will be the use of board sheathing. Local builders are returning to this method as it provides a vapor open layer in a location within the wall where a barrier to moisture (plywood, OSB) can cause problems in a heavily insulated wall. Plus it's local wood. plus it's more fun - carpenters don't get to cut many actual 1x boards anymore. The exterior will be sealed up with Mento to prevent air movement through the wall - an excellent combination with the board sheathing.

Early Thoughts on the Greenfield Project (architect)

I took a shot at writing down my own thoughts about the Greenfield project I’m doing for my wife’s folks. Sometimes I have so many half-baked ideas in my head that writing them down creates a jelling effect and helps me to clarify and focus my efforts. I’m planning on documenting this project to a much higher level than I have in the past, partly because we are assembling something of a dream team to get this done and partly because I am using this project to redefine how I work in order to bring my own practice to a higher level. I have encouraged the others to start writing as well and some of that will show up here on the blog as well for a more well-rounded perspective. We are currently exploring the feasibility of doing this house as a Passive house and seeking certification. I hope, as usual, to show what can be accomplished when a highly functional and customized plan is also an emotionally uplifting place to live. This projects continues my exploration into the emotional aspects of “home” and how to use architecture to augment and reinforce the emotional connection to place. Phew! What have I to gain from doing this project as a full-on Certified Passive House? So what if the winter heating bills drop from $75/month to $25/month? Is that really worth all the extra effort and expense to go through certification? We don’t know the answer to that yet. “Let me run some numbers” as the engineer or accountant would say. Passive house has cache. It attracts media. There is huge marketing potential. The clients (my in-laws) are understandably interested in that aspect of it - it relates to their son-in-law’s ability to financially support his wife and children. I want to do more of this type of work in the future and will I ever get such a good opportunity to gain exposure, attention and build a reputation that to do a very attractive and relevant project at this highest level… and market it to the greatest extent possible. I have seen that model propel other firms into the limelight so I am aware of what power and potential in inherent in this thinking. Otherwise- My own limited knowledge of Passive House indicated that this house as designed thus far could attain Passive House certification with minimal extra effort. I’m a Certified Passive House Designer – CPHD with the international credential but I have little practical experience. This project could be a great way to gain that experience. The most effort and extra money will probably be in soft costs – hiring someone with experience to do the energy modeling, advise on detailing and assist in the certification process. With this project we are also formalizing a fairly progressive project delivery process that I am realizing is crucial to creating high performance buildings. This represents the direction my own business model is headed in. I have, in the past, followed both the more traditional architect route where I work with clients to design and detail a project and we shop it out to builders. I have also worked (more often) in a more design-build model where the builder is integrated into the process from very early in the process. That has been my preferred method of project delivery but I am realizing that to provide the highest levels of service, I need to fill in some gaps. I can’t do everything and I don’t have expertise in everything so I’m bringing in people to help fill the traditional gaps. Subcontractors as well need to be on board as part of the team at a much earlier stage and need to be aware that they will be asked to perform at a very high level of professionalism. Part of my job is to make that as easy as possible for them through design and detailing. I am working on this project with Mel Baiser of Baiser Construction Management and Chad Mathrani of Vermont Natural Homes both of whom have training in passive house detailing and construction. They understand what it takes to reach that highest level of building excellence. And considerable enthusiasm to do so. We are pouring over the details as fast as I can draw them up to insure that no stone is left unturned. The process requires a high level of integration at this early stage in terms of product selection, integrated assembly, cost (and relative costs). Assumptions are challenged and vetted and everything will be put down on paper before the project is staked out on the site which is under considerable snow at the moment. We will maintain a process blog as part of Vermont Architect to provide a window into this process. Blog readers and Bluetime Collaborative facebook followers have already seen some early schematic design images of this project. Stay tuned.

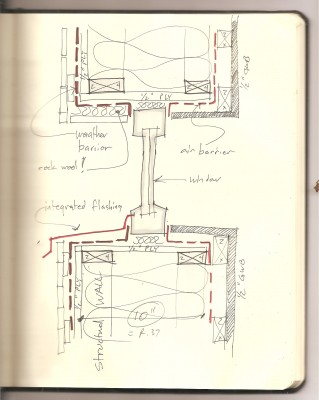

Always know what and where your AIR BARRIER is.

I’m working on detailing out a smallish house in Greenfield, MA. We probably won’t go full Passive House on this but we will look at what additional costs and detailing it would take. And if we’re close… We are doing some novel (to me) stuff for the shell of the house that, I suspect, will become more standard practice for me in years to come.

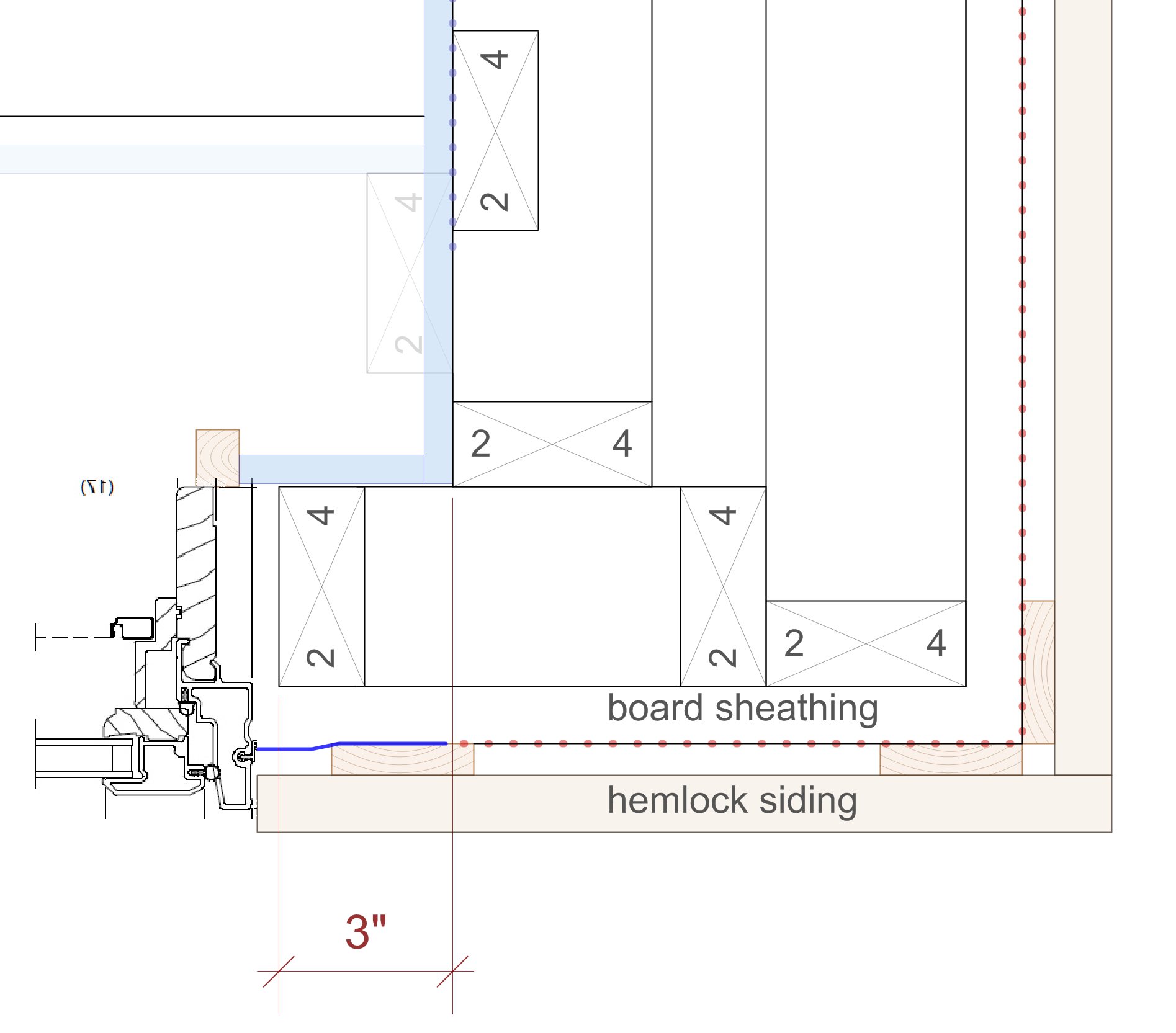

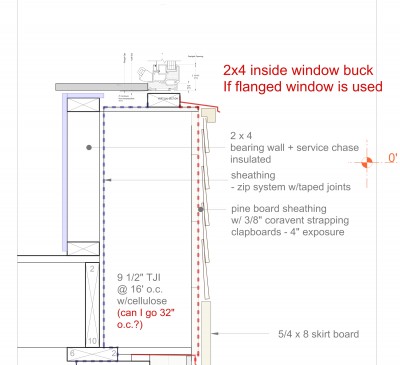

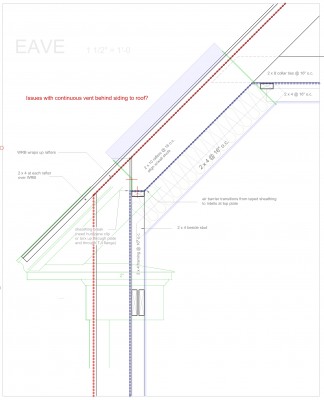

Here are some “progress print” detail drawings from the plan set. My drawings tend to look a bit different than most architect's drawings due to two things: The time I spent wielding a hammer and trying to interpret my own drawings and the fact that I have worked as a sole practitioner for so long and have developed my own graphic style. I should add to that a third thing – my knowledge of building science informed best practices.

We are doing some novel (to me) stuff for the shell of the house that, I suspect, will become more standard practice for me in years to come.

Here are some “progress print” detail drawings from the plan set. My drawings tend to look a bit different than most architect's drawings due to two things: The time I spent wielding a hammer and trying to interpret my own drawings and the fact that I have worked as a sole practitioner for so long and have developed my own graphic style. I should add to that a third thing – my knowledge of building science informed best practices.

The first thing you will notice about these drawings is actually the most important thing. The red and blue dotted lines represent the weather resistant barrier and the air barrier respectively. If your drawings don’t have at least the air barrier called out in the sections, (and continuous around the thermal envelope) The drawings are incomplete. I have been getting picky in my detailing about how to make the air barrier both easy to achieve and durable. In my opinion, relying on painted sheetrock to serve as an air barrier just doesn’t cut it – certainly not for the next 100 years.

Many builders and architects in the Northeast US are still building 2x6 walls with fiberglass batts and a poly vapor barrier. That’s how I learned to do it when I was just starting out in the 90’s. I also opened up a number of walls built that way that were full of mold.

-

Good

builders don’t build this way anymore. Check the Building Science Corporation website for some pictures of what can go wrong.

One part of building science is probability and statistics. I often hear builders say “I’ve always built that way and I’ve never had any problems” - that you know about. But those builders are only looking at 50 or 100 projects. Luck plays a part here. What happens when you look at thousands or even tens of thousands? You start to see some patterns emerge and you start to see the luck factor drop out of the equation. You are able to formulate some best practice standards for a number of things including durability, air quality, energy use and even catastrophic failure. I prefer to work with builders who are informed about building science and involved in the discussion.

That’s easy here in the Southeastern Vermont area home of Building Green area, home of Building Green and SEON which sponsors a well-attended monthly building science discussion group and learning circle. – If anyone wants to get something like this started in their own community, send Guy an email at the address in their website.

I owe it to my clients to help them get the best constructed project possible. That, in addition to the most functional, aesthetically appropriate, finely crafted project possible.

– Oh and the budget thing too –

Detailing such as represented in these drawings is also very much about budget. The goal is to bump up the levels of insulation, air tightness, r value of windows etc. so that we can eliminate the traditional boiler and heat distribution system in favor of a minisplit heat pump which is more of an appliance than a system and dramatically less expensive. (I think this link is a GBA pro only link - subscription) For those without a subscription try this alternative Ideally, it becomes a wash cost wise but with the added bonus of very low monthly heating and cooling costs. Those savings alone can represent hundreds of dollars per month.

Thermal bridging and Air sealing - simplified

Just a quickie about thermal bridging and air sealing. I can explain it in way fewer words and terms and scientific-ness than what you find when you go looking for information on the web. Thermal bridging is when there is too much stuff that is not insulation in a section of exterior wall. This includes most traditionally framed houses. Especially near outside corners and around windows. In the cold of winter, the inside room surface of these areas stay much cooler than the surrounding room temperature and condensation occurs, then mold.

Improper air sealing is when your builder tells you your house needs to breathe and he's not talking about an air exchange system. Improper air sealing allows air to enter your house through tiny pathways through and near these moldy areas. The mold spores are then breathed in by your children.

Get it?

Observations from Rachelle (my co-#1 fan)

Bob has been asking me for some time to write a guest blog entry and since he has happily been to busy of late to write much himself, I thought this was a good time to finally make good on my promise to do so. Last year, I had a visit with an old friend who had recently moved back to the area. I hadn't seen her for a while, and it was the first time I'd seen her new house since it was just a partially-erected timber frame. It was lovely to see my friend after such a long gap, and also fodder for pondering and a blog entry.

The house was nice—open, tasteful, bright and spacious (huge by our standards) and it fulfilled their goal of functioning as somewhat of a community gathering place as well as a home. For example, they were holding a weekly meditation group in a specially designed meditation/yoga area. But I couldn't help thinking that if Bob had designed it, it could have met their needs so much more simply, elegantly and with much less square footage.

Of course I said nothing (how can you say something like that and what would be the point?) as I had said nothing during their design process. It seems rather self-serving to say to a friend who's designing their own dream house, “you know, you should really consider hiring my husband.”

But what I learned next makes me question whether that was really the best approach. When somebody builds a house, you expect them to be excited, even jubilant with the result. Instead, my friend told me that she felt like she had PTSD. There wasn't a single corner of the house she could look at without dredging up the stressful arguments with contractors over that bit of construction. She wished she could be rid of the house, but they were sunk in it for so much more than market value, that wasn't an option.

The biggest mistake they had made was to get sweet-talked by the GC into inadequate planning and problem-solving. One thing Bob stresses to all his clients is how much easier it is and how much cheaper it is to work out problems on paper. My friend believed her charismatic contractor that they could figure it all out as they went. What she figured out is that it's very expensive to pay for an entire crew to stand around and wait while hasty compromises are made.

I could go on, but you get the point. My friend's unfortunate house-building experience is a classic example of why it pays to pay for someone good to be on your side. Of course, that's no guarantee of satisfaction either, I suppose. I'm thinking of some clients who fired Bob a few years back after he showed them a rendering of what the addition floor plan they loved would look like in elevation. Not at all what they'd expected. You'd think they might have been appreciative to discover that after a few hours of design time rather than mid-construction. No accounting for people. It's now once again been a while since I caught up with that friend. I hope she's come to peace with her process by now, and that she's enjoying her home. And if another friend embarks on the process of building a home? I wonder if I'll serve them by being self-serving. I'll probably just give them some generic advice about working all the kinks out that they can on paper, and leave it at that. After all, my friends all know I'm married to an architect.

Thinking ahead

HA! This happens a lot. I just got a call from a contractor who wanted to modify roof trim on an addition to make it both easier and he thought it would look better. Which it would except that a future phase of the project involves adding a porch in such a way that the frieze on the addition becomes the casing for the porch beam. The continuity was important to the client to calm that side of the building. In the image, the red over the window is where the contractor wanted to case the window with 1 x 4 thus creating a narrower frieze board. When that line got over to the porch on the left it would have to drop down to case in the porch beam. Not smooth. On the windows above, the casing for the windows is independent and below the frieze which is preferable, however, I was setting the three lower windows as high and large as I could over a countertop to maximize light into a deep room. We were squished also in terms of the roof in order to get it well under the upstairs windows. Especially over the porch area. The contractor's solution would be fine and what I would have designed were it not for the open porch to the right. I found, during the years I worked as a carpenter, that it was easy to concentrate on the task at hand and lose sight of the overall picture. As a designer, sometimes I'll make a foundation more complicated in order to make framing or trim more simple. Or sometimes I'll do things in a more complicated fashion due to an aesthetic historical precedent. (Isn't much of traditional design like that?) Sometimes I will complicate things to make the end result look simple. Sometimes I complicated things just because I can be really really picky.

I found, during the years I worked as a carpenter, that it was easy to concentrate on the task at hand and lose sight of the overall picture. As a designer, sometimes I'll make a foundation more complicated in order to make framing or trim more simple. Or sometimes I'll do things in a more complicated fashion due to an aesthetic historical precedent. (Isn't much of traditional design like that?) Sometimes I will complicate things to make the end result look simple. Sometimes I complicated things just because I can be really really picky.

If you want your house to breathe, give it a set of lungs.

I had another comment recently from a builder who wants to build a house that breathes. I started to reply in an email and then decided to put it hereon the blog instead. What we are doing nowadays in the world of high performance homes is based on studying hundreds of thousands of houses built in the last half century that have failed (which includes the majority of 70's and 80's super-insulated and passive solar homes in the northeast) and applying those lessons to building a durable house nowadays. Houses from before that time period that failed for one reason or another are mostly gone and many of those that remain are simple piggy banks for big oil. We put our money in and the oil companies take it out. Simple. (usually, I like simple but...) For the past few decades, builders in the northeast have been living in a vacuum while the northern Europeans and Canadians paid much more attention to how houses fail, learning from them and adapting. Now the conversation is opening up again and we are taking a seat at the table.

I have lived in houses that breath my whole life. It sucks. Aside from the part where you have to give your money to someone else just to not freeze to death in the winter, there is the comfort aspect of things. Houses I have lived in have never been all that comfortable whether in terms of temperature or moisture levels or even wiping mildew off the window sills. Now, with two children, I worry about the air quality and mold issues inherent in my house that breathes. I would rather be able to seal up the house in the winter and be confident that I was breathing fresh Vermont air all the time than have to step outside for a breath of fresh air or open up the doors and windows if I screw up on getting the woodstove going. Six months out of the year, I would still have the choice to open the windows and turn off the HRV.

We do seem to have more summer moisture and humidity problems than we used to but we also have access to more durable and proven materials and building methods. Some builders and architects are taking advantage of this but most are building the same way they did 20 years ago despite all the failures. A house that breathes and has little or no insulation is a barn and If you want to heat it, that means coming to terms with giving your money away. Jesse Thompson says "People breath air through their lungs, not their skin. Why should houses be any different?" If you want your house to breathe, give it a set of lungs.

There are a range of options for doing this from exhaust only bathroom fans and range hoods (simple and cheap but where does the makeup air come from in a very tight house?) to a full-on Heat Recovery Ventilation System or HRV. These are also fairly simple and effective although significantly more expensive but have the added advantages of recovering much of the heat from the outgoing air as well as providing fresh incoming air exactly where you want it. For more information just type "HRV" or "house ventilation" into the search box on Green Building Advisor and start reading.

Window installation in a super-insulated wall

Designing a Super-insulated wall with good drying potential and good air sealing is easy. But the Devil is in the windows. With passive house level construction we want the window to be recessed toward the middle of the opening and the middle of the adjacent insulation layer. This is about thermal bridging and heat loss. An advantage that I've found is that it can potentially simplify the flashing which is certainly a welcome idea. Window and door installation has become increasingly complex over the past decade especially with exterior foam details. (I try to stay away from that) What I'm looking at in this sketch is how flashing for siding can be decoupled from flashing for the window to a great extent. Does the siding even need flashing anymore? Depends on how you do the siding. With some Rain screen siding details, perhaps not! Windows are now coming with really nice integrated sill flashing - you specify the depth when you order. This makes for a much more integrated and seamless system which should have long term durability advantages over what we have been doing up until now. What is missing from this drawing is an exterior layer of rock wool insulation to keep the sheathing warm (not rigid foam !) A more expensive detail and this may be less important when using cellulose than fiberglass insulation but is a detail I would certainly do on my own home. The other option is to use more of a Larsen truss system similar to what Chris Corson is doing in Maine with no exterior sheathing. It is A tough sell around here to leave the insulation protected only by a weather barrier such as Mento plus. The conversation on building science is terribly interesting and seems to be resolving itself towards simplicity as we gain knowledge and experience about what works and what doesn't and develop products and materials based on our increasing knowledge base. Of course, 93% of builders and architects aren't really paying much attention.

Designing a Super-insulated wall with good drying potential and good air sealing is easy. But the Devil is in the windows. With passive house level construction we want the window to be recessed toward the middle of the opening and the middle of the adjacent insulation layer. This is about thermal bridging and heat loss. An advantage that I've found is that it can potentially simplify the flashing which is certainly a welcome idea. Window and door installation has become increasingly complex over the past decade especially with exterior foam details. (I try to stay away from that) What I'm looking at in this sketch is how flashing for siding can be decoupled from flashing for the window to a great extent. Does the siding even need flashing anymore? Depends on how you do the siding. With some Rain screen siding details, perhaps not! Windows are now coming with really nice integrated sill flashing - you specify the depth when you order. This makes for a much more integrated and seamless system which should have long term durability advantages over what we have been doing up until now. What is missing from this drawing is an exterior layer of rock wool insulation to keep the sheathing warm (not rigid foam !) A more expensive detail and this may be less important when using cellulose than fiberglass insulation but is a detail I would certainly do on my own home. The other option is to use more of a Larsen truss system similar to what Chris Corson is doing in Maine with no exterior sheathing. It is A tough sell around here to leave the insulation protected only by a weather barrier such as Mento plus. The conversation on building science is terribly interesting and seems to be resolving itself towards simplicity as we gain knowledge and experience about what works and what doesn't and develop products and materials based on our increasing knowledge base. Of course, 93% of builders and architects aren't really paying much attention.

SEON - building science learning group in Brattleboro

SEON or Sustainable Energy Outreach Network is a relatively new organization in the Brattleboro area. The mission from the website is to “establish a network that promotes Southeastern Vermont and its neighboring regions as a vibrant center of sustainable energy.” which sounds rather vague. I think they are trying to feel out exactly what their role in the community will be. They are off to a great start by sponsoring a monthly building science learning group. This is in a presentation and discussion format, often moderated by Peter Yost of EBN and GBA, with topics brought to the group by the participants who are mostly local builders.

SEON or Sustainable Energy Outreach Network is a relatively new organization in the Brattleboro area. The mission from the website is to “establish a network that promotes Southeastern Vermont and its neighboring regions as a vibrant center of sustainable energy.” which sounds rather vague. I think they are trying to feel out exactly what their role in the community will be. They are off to a great start by sponsoring a monthly building science learning group. This is in a presentation and discussion format, often moderated by Peter Yost of EBN and GBA, with topics brought to the group by the participants who are mostly local builders.

“Each month over 20 building professionals meet for 3 hours to advance their understanding of building science principles especially as it pertains to the problems they confront on their worksite. Case studies are reviewed, root cause analysis is applied, hypotheses are generated based on the physics of building science. The challenge is that there are no clear solutions to many of the problems. We are still learning in the midst of uncertainty and ever changing product design. Hence the need for ongoing discussions.”

The discussions are at a pretty high level but are very accessible to everyone as a goal is to bring the general building science knowledge level in this area to a very high level, making this area even more of a hotbed for green building than it is currently. Many of these folks are way beyond the standard hour and a half presentation you tend to get in symposiums such as at Better Buildings up in Burlington – not to knock that one (definitely go!) - and, perhaps had been feeling the need for much more in-depth and collaborative discussion relevant to their own daily work.

As an architect, this is a joy to see because these are the folks that I get to work with on a regular basis. As an architect, I often have to provide a basic education in building science to both the builder and the client. Having a builder who is “hip” to green building and building science issues makes my job much easier.

I encourage any local builders, architects and designers, and any folks involved with building and energy to check this group out. They usually meet from 3 to 6, once a month on a Wednesday or Thursday. Where and when can be found on the website calendar.

Building Science gives me a headache.

Building Science gives me a headache. I read the usual sites: Greenbuildingadvisor.com, building science.com, plus a few others, I attend seminars, I get all the proper magazines, I belong to the correct organizations such as the USGBC. I'm a good little architect. But I am confused. The more I dive into building science the more questions I have – and therefore the less authoritative I sound in front of clients and I don't think clients want their architect to sound wishy-washy. Let me start by explaining building science. Building science is largely based on large amounts of cumulative experience (databases) probability and statistics. As I recall the story, Joe Lstiburek and his pals started buildingscience.com after going into thousands of houses near airports to upgrade insulation levels to provide better sound proofing. They saw lots of bad things (rot). This provided them with the beginnings of a large database of how houses are built in terms of what works and what doesn't – what details and systems result in greater failure rates as well as what works. A much larger database than Joe builder down the road who has built a few dozen houses in the past thirty years. Smart Joe-the-builders (notice I'm not saying Bob the builder...there's a reason for that...I'm tired of Bob jokes okay?) anyway, smart Joe-the-builders recognize that Joe-the-building-scientist has collected way more information and experience all in one place and is offering it out for free – or just about. Smart Joe-the-builders know that construction is a high liability proposition and anything they can do to limit that liability will help them sleep at night. You can probably replace Joe-the-builder with Bob-the-architect in the previous sentences and it would work fairly well. These Joe-the-building-scientist types are also very often engineers (which means they look at numbers a lot and when they build houses for themselves they cannot justify having windows because it blows their heat loss calculations right out...well...the window) Being numbery-engineery sorts they are able to take their observations from the databases of thousands of houses and figure out more specifically what is happening to cause the problems. Thus we have much more information now about, for instance, the importance of air sealing, controlled ventilation and gapping the siding away from the sheathing than we did ten years ago.

As an architect, fabulous new products come across my desk every day and the magazines are filled with advertisements. How to sort through all this? We architects look to building science to help us separate the wheat from the chaff. Who has done a study on this new and great sounding product? Was the study valid enough to take seriously? What is the builder input and reaction to this new product? What are the warranties? What is the science that the amazing claims are based upon. As an architect I realize that there is always someone with way more expertise and experience than myself and part of my job is to seek them out.

My thoughts along these lines started as an ongoing conversation with an equally confused builder friend of mine. This builder is a rare one who drags his crew to building science talks and seminars and is buddies with Alex Wilson et. al. over at Building Green. We have been trying to figure out what is the perfect enclosure for our local climate in terms of: Ease of construction – what can the carpenters understand and get behind? Budget constraints – most clients around here are have very limited budgets and just want more room; green building and lower heat bills through super-insulation are secondary. Simplicity – this cannot be understated as it affects all other issues. Use of commonly available and understood building materials and systems. Performance – why put tons of insulation in a wall if there is inadequate air sealing which renders the insulation nearly useless? So far, it has been our local experience that proprietary systems cost, at least marginally, more. There are some very good systems out there it should be noted, all with their share of positives and negatives What has a proven track record of performance with building science to back it up. Does a less than perfect installation negate any advantages or potentially cause more issues than a business as usual system of construction? How much of a difference is it really going to make – This may need some explaining and I will use the example of my own house. I burn about 4 cord of wood per year to stay cozy and warm. My house is very poorly insulated but fairly tight, mostly due to its simplicity. If I were to invest a large amount of time and money in air sealing, an HRV system, and more insulation, perhaps I might only burn 3 cords of wood per year. Big deal. But if I were heating with oil or gas it would be. In the locale where I live and work, this is the type of metric that must be addressed in any project. The builder, his crew and myself marched over to the offices of Building Green and sat ourselves down in the company of Peter Yost, a building scientist sort whom many of you would be familiar with from GreenbuildingAdvisor.com. Peter proceeded to confuse us all the more as he waved lots of numbers around. But we came out of the meeting with a reinforced sense of the importance of and methods of achieving a proper air seal (assume the wall will get wet – now how and when does it dry?) and the importance of dealing with gross water first and foremost (gross water is what comes out of the sky and dumps all over our buildings and splashes around a lot). We also came out with the increased sense that we need to look at enclosures as “systems” where one part of a system can only work optimally if used in a certain conjunction with other parts of the system. Phew. Did I mention that I have a building science headache? We also came out with more questions than we went in with. Sigh...

In an upcoming post I shall include parts of an online conversation between myself and other architect friends along these lines. Then I shall conclude with my inconclusive findings and recommendations.

A client's addition/renovation process blog

http://musingsfromdave.blogspot.com/Here is a process blog from some folks I helped to design an addition for last winter. It was the sort of project where having an architect payed off (if I remember some of the early schemes they came to me with). We were able to phase the project, and with the help of some very thorough pricing by the contractor, make some big decisions before starting construction. The original house was not unlike my own in size - bigger kitchen and only one bedroom though. They wanted a sunny spot to soak up morning sunshine. I gave them four and labeled them as such on the plans.