I took a shot at writing down my own thoughts about the Greenfield project I’m doing for my wife’s folks. Sometimes I have so many half-baked ideas in my head that writing them down creates a jelling effect and helps me to clarify and focus my efforts. I’m planning on documenting this project to a much higher level than I have in the past, partly because we are assembling something of a dream team to get this done and partly because I am using this project to redefine how I work in order to bring my own practice to a higher level. I have encouraged the others to start writing as well and some of that will show up here on the blog as well for a more well-rounded perspective. We are currently exploring the feasibility of doing this house as a Passive house and seeking certification. I hope, as usual, to show what can be accomplished when a highly functional and customized plan is also an emotionally uplifting place to live. This projects continues my exploration into the emotional aspects of “home” and how to use architecture to augment and reinforce the emotional connection to place. Phew! What have I to gain from doing this project as a full-on Certified Passive House? So what if the winter heating bills drop from $75/month to $25/month? Is that really worth all the extra effort and expense to go through certification? We don’t know the answer to that yet. “Let me run some numbers” as the engineer or accountant would say. Passive house has cache. It attracts media. There is huge marketing potential. The clients (my in-laws) are understandably interested in that aspect of it - it relates to their son-in-law’s ability to financially support his wife and children. I want to do more of this type of work in the future and will I ever get such a good opportunity to gain exposure, attention and build a reputation that to do a very attractive and relevant project at this highest level… and market it to the greatest extent possible. I have seen that model propel other firms into the limelight so I am aware of what power and potential in inherent in this thinking. Otherwise- My own limited knowledge of Passive House indicated that this house as designed thus far could attain Passive House certification with minimal extra effort. I’m a Certified Passive House Designer – CPHD with the international credential but I have little practical experience. This project could be a great way to gain that experience. The most effort and extra money will probably be in soft costs – hiring someone with experience to do the energy modeling, advise on detailing and assist in the certification process. With this project we are also formalizing a fairly progressive project delivery process that I am realizing is crucial to creating high performance buildings. This represents the direction my own business model is headed in. I have, in the past, followed both the more traditional architect route where I work with clients to design and detail a project and we shop it out to builders. I have also worked (more often) in a more design-build model where the builder is integrated into the process from very early in the process. That has been my preferred method of project delivery but I am realizing that to provide the highest levels of service, I need to fill in some gaps. I can’t do everything and I don’t have expertise in everything so I’m bringing in people to help fill the traditional gaps. Subcontractors as well need to be on board as part of the team at a much earlier stage and need to be aware that they will be asked to perform at a very high level of professionalism. Part of my job is to make that as easy as possible for them through design and detailing. I am working on this project with Mel Baiser of Baiser Construction Management and Chad Mathrani of Vermont Natural Homes both of whom have training in passive house detailing and construction. They understand what it takes to reach that highest level of building excellence. And considerable enthusiasm to do so. We are pouring over the details as fast as I can draw them up to insure that no stone is left unturned. The process requires a high level of integration at this early stage in terms of product selection, integrated assembly, cost (and relative costs). Assumptions are challenged and vetted and everything will be put down on paper before the project is staked out on the site which is under considerable snow at the moment. We will maintain a process blog as part of Vermont Architect to provide a window into this process. Blog readers and Bluetime Collaborative facebook followers have already seen some early schematic design images of this project. Stay tuned.

Always know what and where your AIR BARRIER is.

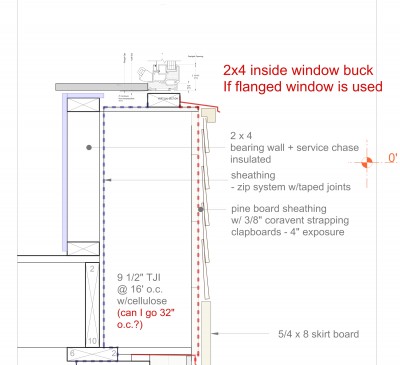

I’m working on detailing out a smallish house in Greenfield, MA. We probably won’t go full Passive House on this but we will look at what additional costs and detailing it would take. And if we’re close… We are doing some novel (to me) stuff for the shell of the house that, I suspect, will become more standard practice for me in years to come.

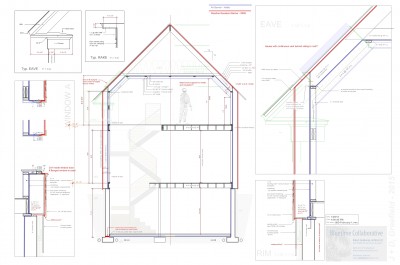

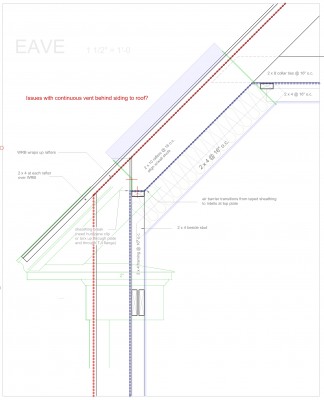

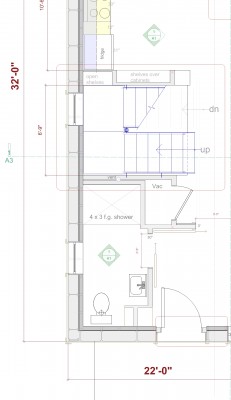

Here are some “progress print” detail drawings from the plan set. My drawings tend to look a bit different than most architect's drawings due to two things: The time I spent wielding a hammer and trying to interpret my own drawings and the fact that I have worked as a sole practitioner for so long and have developed my own graphic style. I should add to that a third thing – my knowledge of building science informed best practices.

We are doing some novel (to me) stuff for the shell of the house that, I suspect, will become more standard practice for me in years to come.

Here are some “progress print” detail drawings from the plan set. My drawings tend to look a bit different than most architect's drawings due to two things: The time I spent wielding a hammer and trying to interpret my own drawings and the fact that I have worked as a sole practitioner for so long and have developed my own graphic style. I should add to that a third thing – my knowledge of building science informed best practices.

The first thing you will notice about these drawings is actually the most important thing. The red and blue dotted lines represent the weather resistant barrier and the air barrier respectively. If your drawings don’t have at least the air barrier called out in the sections, (and continuous around the thermal envelope) The drawings are incomplete. I have been getting picky in my detailing about how to make the air barrier both easy to achieve and durable. In my opinion, relying on painted sheetrock to serve as an air barrier just doesn’t cut it – certainly not for the next 100 years.

Many builders and architects in the Northeast US are still building 2x6 walls with fiberglass batts and a poly vapor barrier. That’s how I learned to do it when I was just starting out in the 90’s. I also opened up a number of walls built that way that were full of mold.

-

Good

builders don’t build this way anymore. Check the Building Science Corporation website for some pictures of what can go wrong.

One part of building science is probability and statistics. I often hear builders say “I’ve always built that way and I’ve never had any problems” - that you know about. But those builders are only looking at 50 or 100 projects. Luck plays a part here. What happens when you look at thousands or even tens of thousands? You start to see some patterns emerge and you start to see the luck factor drop out of the equation. You are able to formulate some best practice standards for a number of things including durability, air quality, energy use and even catastrophic failure. I prefer to work with builders who are informed about building science and involved in the discussion.

That’s easy here in the Southeastern Vermont area home of Building Green area, home of Building Green and SEON which sponsors a well-attended monthly building science discussion group and learning circle. – If anyone wants to get something like this started in their own community, send Guy an email at the address in their website.

I owe it to my clients to help them get the best constructed project possible. That, in addition to the most functional, aesthetically appropriate, finely crafted project possible.

– Oh and the budget thing too –

Detailing such as represented in these drawings is also very much about budget. The goal is to bump up the levels of insulation, air tightness, r value of windows etc. so that we can eliminate the traditional boiler and heat distribution system in favor of a minisplit heat pump which is more of an appliance than a system and dramatically less expensive. (I think this link is a GBA pro only link - subscription) For those without a subscription try this alternative Ideally, it becomes a wash cost wise but with the added bonus of very low monthly heating and cooling costs. Those savings alone can represent hundreds of dollars per month.

A Smallish House in Massachusetts

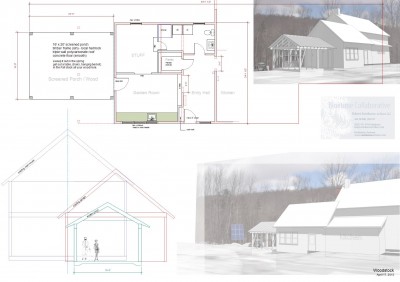

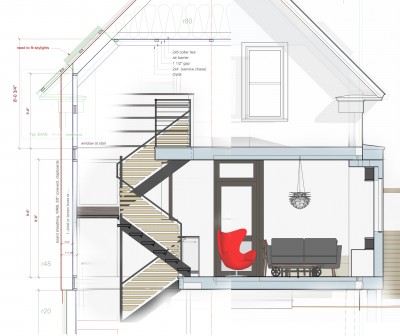

I am working on a 1400 s.f house in Massachusetts. Given that the walls are over a foot thick, the actual square footage is quite a bit less (about 1200). The extra insulation (and cutting edge building science) allows us to forgo a heat system other than a relatively inexpensive minisplit - and monthly fuel bills. Here are a few images of what I'm up to. no fancy rendering for now, just the Sketchup model and some Vectorworks CAD drawings.

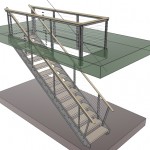

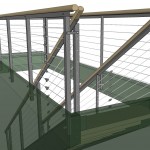

I spent a fair amount of time detailing the steel and wood stairs in Sketchup as I have found that is the only way for me to really figure out every nut and bolt and refine the design to the level that I am comfortable with before construction drawings. I like to approach the stair as sculpture with every piece exact and connections "just so". Thus I am able to design something that is quick and easy to assemble with just the right amount of "fudge space" built in.

The floor plans have shrunk and simplified from the last version becoming more functional and comfortable.

Mod Ski Home in VT - interiors

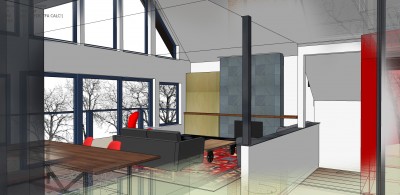

I'm working on fleshing out the interiors for this addition renovation project here in Vermont.

G-Jan-4 from Robert Swinburne on Vimeo.

Scandinavian influence in Vermont

AmesHill October29 from Robert Swinburne on Vimeo.

This one will have a bit of a rustic Scandinavian feel to it. And be super-insulated of course.

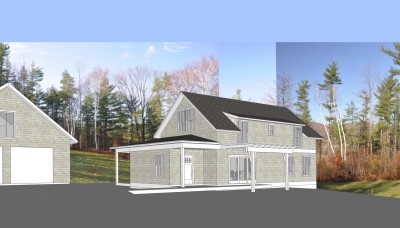

Progress on Mod ski home in Vermont

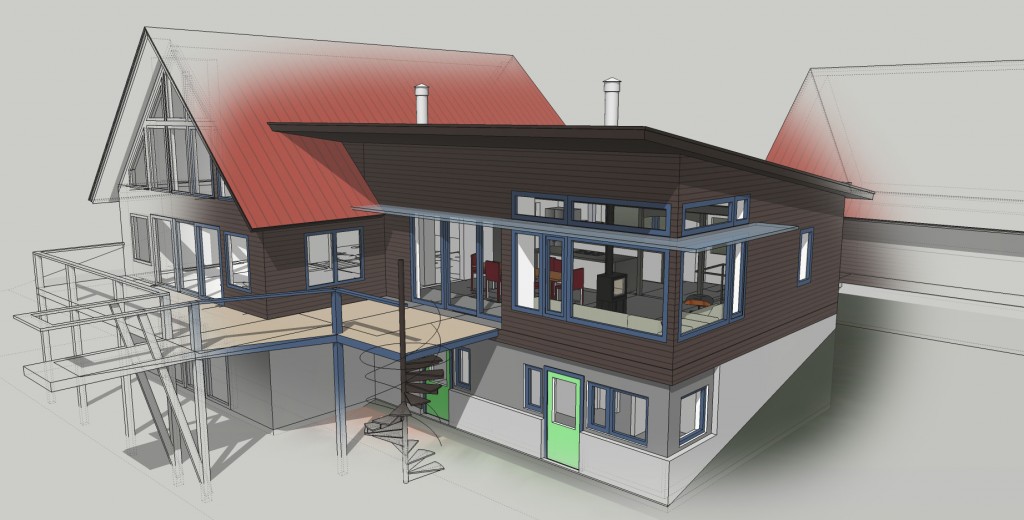

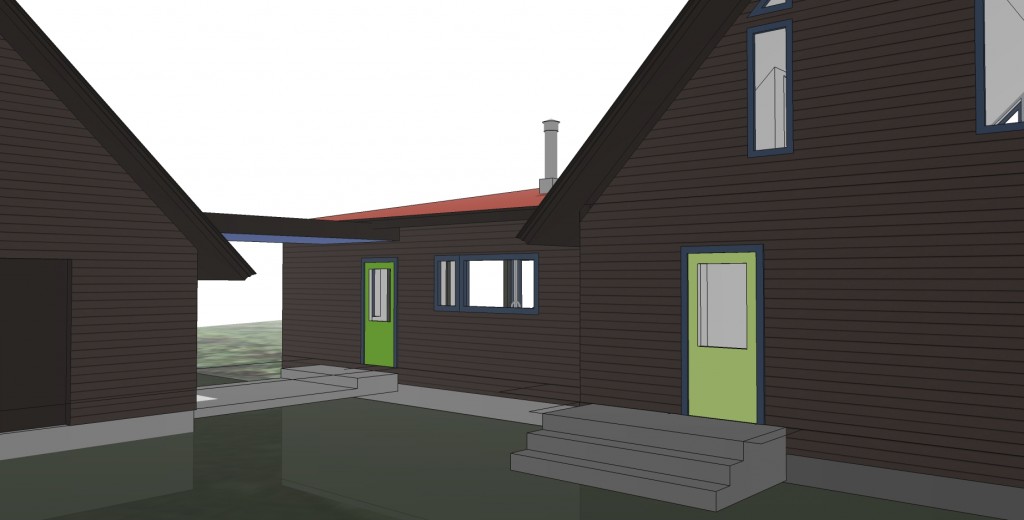

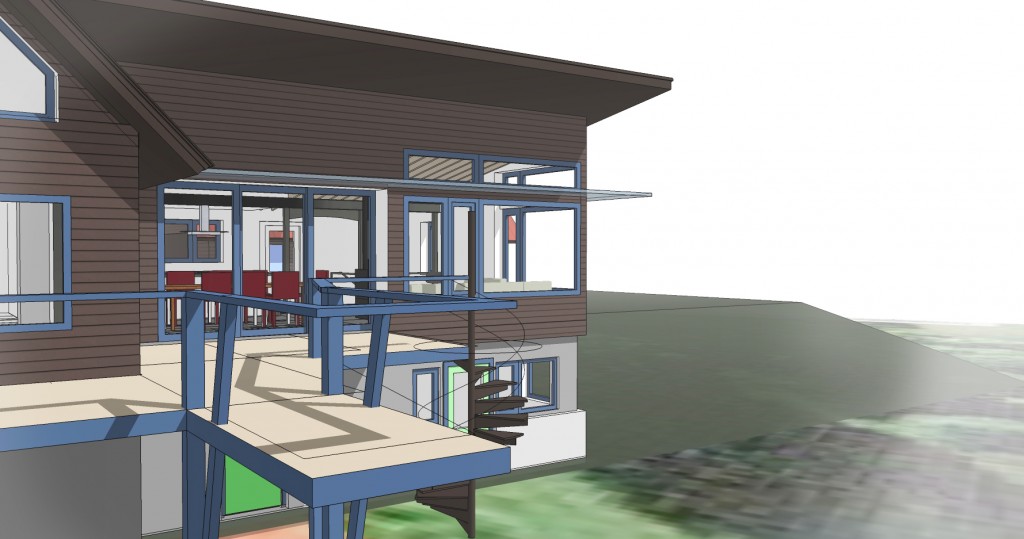

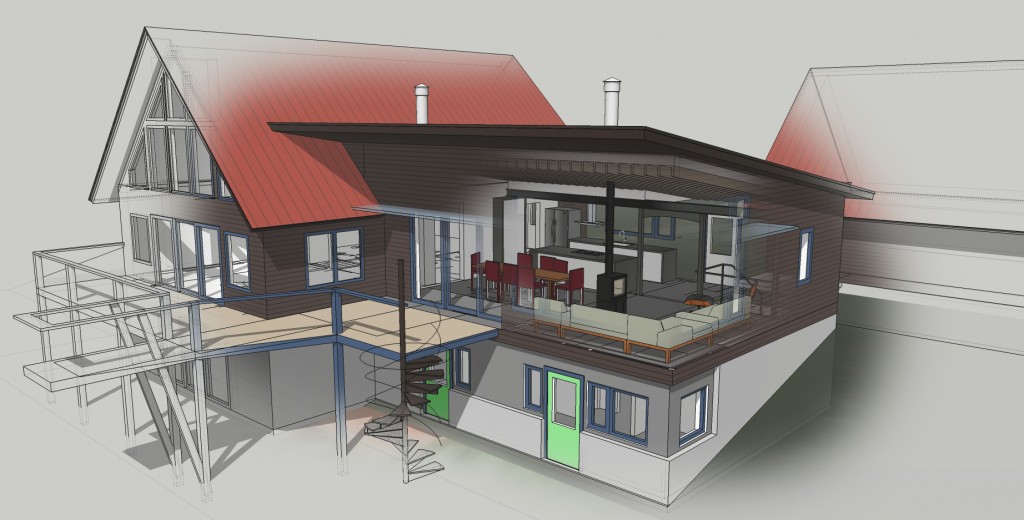

One of the projects I'm working on is an addition to and renovations of a ski home in Vermont. The main house is well built and and other than a maroon and pink bathroom and rather 80's finishes, we are not doing anything too major to it. We are locating a family room addition between the existing house and garage which will provide a much nicer kitchen and living area plus additional bunkrooms and a multi-user bath on the basement level. I'm sticking with the dark clapboard and red standing seam roof of the existing as I think it provides a nice base for some fun things to happen with color at the doors and windows.

We are locating a family room addition between the existing house and garage which will provide a much nicer kitchen and living area plus additional bunkrooms and a multi-user bath on the basement level. I'm sticking with the dark clapboard and red standing seam roof of the existing as I think it provides a nice base for some fun things to happen with color at the doors and windows.

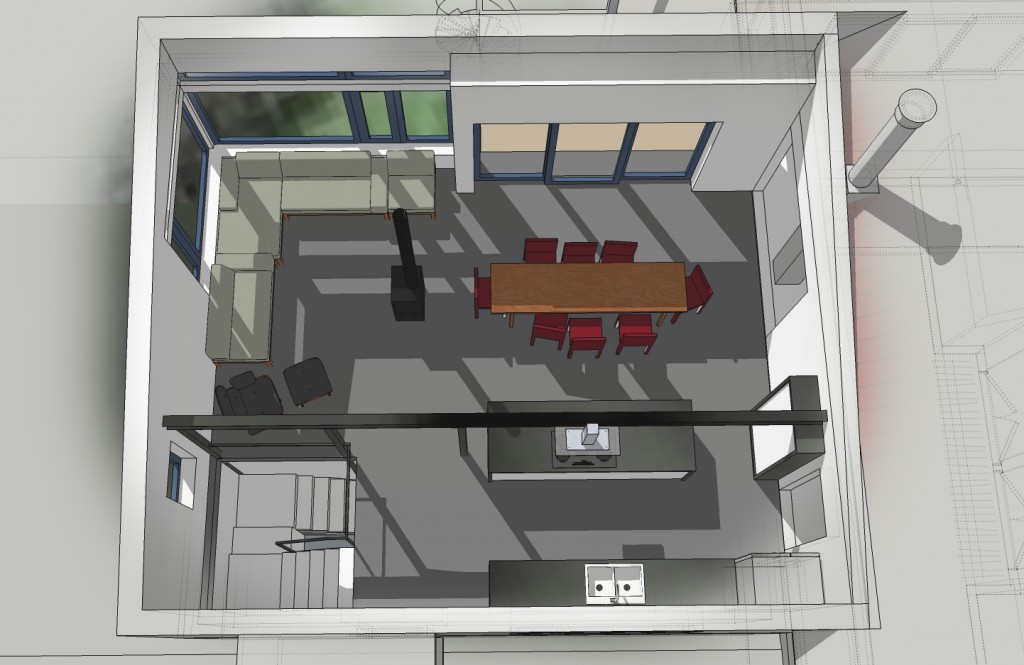

I am using big windows, wood, steel etc to create a warm, modern and relaxed space for lots of people to be in.

I am using big windows, wood, steel etc to create a warm, modern and relaxed space for lots of people to be in.

Here is the current plan:

Here is the current plan:

and I put together a few videos of the sketchup model

and I put together a few videos of the sketchup model

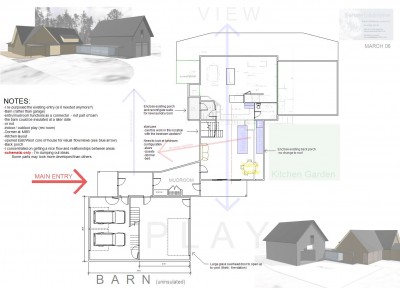

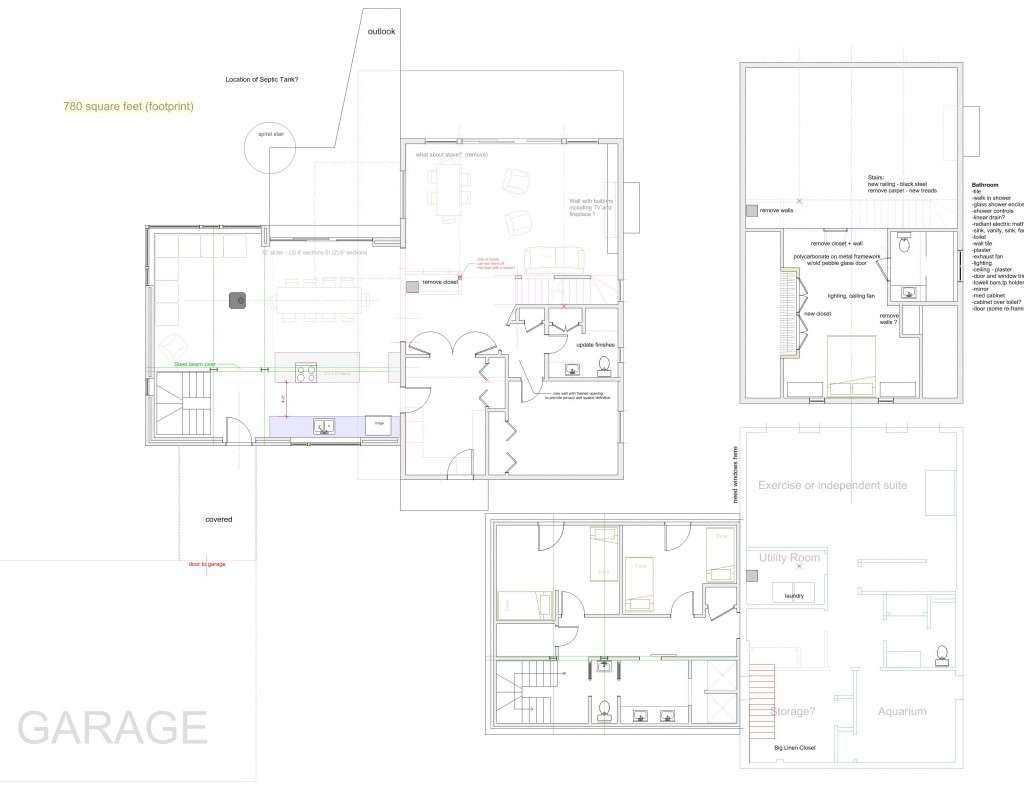

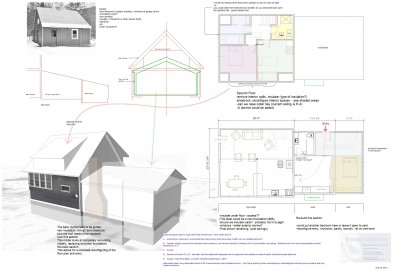

Pre-Design as an initial feasibility study

I often need to spend minimal time - 10 to 20 hours at my hourly rate - to do a simple master planning/feasibility study to explore what can be done to an existing house and if it's worth it. This process includes measuring existing conditions as much as is needed, photos, a thorough initial client meeting, thinking, sketching, some schematic design, modeling, more thinking, writing lists and generally trying to pare down the simplest solution to the client's goals. The result is a .pdf file which attempts to get all this down in a clear format which can be given to a builder for feedback and a VERY rough costing on the various parts and options. I have been assured by other architects that I am ridiculously fast at this in terms of total time spent. Projects often don't progress past this stage as clients realize that it would cost more to achieve what they want than they are able to spend. Or the project gets pared down at this early stage. It is a very useful exercise in saving money by spending some on the architect up front. It seems to be a good graphic way to quickly get a handle on the whole project without committing much in terms of $ from the client or time from me. Here are some examples of three recent projects.

Miscellaneous Musings

I am working on this new small greek revival in Maine. Not the high style Greek Revival with huge columns like you see on banks and government buildings but the small, simple style that is so ubiquitous in New England and doesn't get much attention but everybody knows. I'm designing it to "pretty good house" standards. It is for a family member who lost her house in a fire- we'll see how the budget goes and if the details get watered down as is often the case. She has always loved the Greek Revival look which is more often done wrong than right it seems. I used this sketchup model to push and pull and play with trim and proportion to get it right. I have found that often the frieze board (the wide flat board at the top of the siding under the eaves) often gets shortchanged when the builder frames the house including window openings then discovers that he doesn't have enough room for a properly proportioned frieze.

In any design there is always a lot of back and forth on windows - what works inside may not be so great on the outside etc. so I use the model to really fine tune it in terms of balance, rhythm, symmetry/asymmetry (exterior aesthetics) and light, cross ventilation, views, sun and solar gain, the feel of the room, (function and interior aesthetics)

This is very different from this house which is currently under construction in Vermont which is also a "Pretty Good House" although nearly to the Passive House with Unilux triple glazed windows from Germany But with a modern aesthetic and some really beautiful spaces and materials. We are using raw green 1 x 3 hemlock from a local mill at siding over coravent strapping (rain screen detail) and Mento 1000 weather barrier. The hemlock will dry in place, turn grey and gap in a rougher version of open joint siding often created with Ipe or cedar siding.

I am also studying and reviewing the first three days of Passive House training. The next three days are coming up next week. I am learning a lot of building science stuff that will improve the level of design and service I am able to provide - whether or not I ever get to work on a certified passive house. It was disconcerting, however, to ride the bus into Boston past thousands upon thousands of older houses and housing stock that is rather the opposite of Passive House in terms of energy usage and all the other metrics. You get the feeling of "what's the point". Is passive house a just another trophy for someone building a new house to attain and meaningless in terms of saving ourselves from the coming death, doom and destruction of climate change? I am looking at it in terms of simply building better houses and not thinking about saving the world.

"No matter how many times you save the world, it always manages to get back in jeopardy again. Sometimes I just want it to stay saved, you know? " - Mr Incredible.

Sketchup/Photoshop quick rendering

Tiny House in Context

Until I have as built construction photos this will have to do. I put the Brattleboro tiny house in context replacing the garage behind Vermont Simple House 1 on sale at houseplans.com. I am readying tiny house for sale there as well.

Vermont Simple House 1 stock plans are finished !

Plans are now up and for sale on one of the largest stock plan publishing houses houseplans.com in their "exclusive architects" section!

My plan is to produce a series of similar houses increasing in scale and amenities and see how it goes. Houseplans.com is a progressive company with a good vision as to where the market is headed. They also have huge site traffic numbers. Keeping my fingers crossed. It took me forever to finish the plans and model for this first house, I suspect I am being a perfectionist again.

Plans are now up and for sale on one of the largest stock plan publishing houses houseplans.com in their "exclusive architects" section!

My plan is to produce a series of similar houses increasing in scale and amenities and see how it goes. Houseplans.com is a progressive company with a good vision as to where the market is headed. They also have huge site traffic numbers. Keeping my fingers crossed. It took me forever to finish the plans and model for this first house, I suspect I am being a perfectionist again.

Brattleboro Garage/Studio Addition

A video of a current project - additions to a Brattleboro House

Metal Stair plans for sale

I have the .pdf file of the plans for the Metal stair completed along with the sketchup model for a nine foot floor to floor configuration. At some point I will modify it for a 10 floor to floor as well. Upon purchase, I will send via email the sketchup model (download a sketchup viewer here) and the .pdf plans which you can have printed at your local print shop. The plans constitute a license to construct one (1) stair.

Be aware that I have no legalese stuff on the drawings about safety and local codes.

Be aware that I have no legalese stuff on the drawings about safety and local codes.

current work

My apologies for not posting much recently, overworked and sick kid are my two excuses. Here are some quick model views from a current project. I am developing two schemes for an addition/renovation to a small house, part of which used to be a "sugar shack" (In VT where you make maple syrup in February and March) Here also is a link to my picassa album with some project photos.

Sketchup model

I have been using Google Sketchup extensively in the early stages of projects this year. It helps me zoom in on issues and make good decisions fast. I have also been encouraging clients to download sketchup which is free. I can then send them the file of what I'm working on which is quite small, a blessing with my slow connection. Mastering the visualization tools in sketchup is very easy so clients can play with their design in 3-d. This fosters good communication. Here is a .jpg file of an early sketchup model.