Life is complicated. We all long for a return to some point in our lives when things were simpler. So along the lines of what it is like to be an architect in rural Vermont I thought I'd write up a summary of what my life is like without getting too personal of course.

In 2000, my wife an I were lucky to “accidentally” find and buy a small house with a kitchenette and electric heat on 50 acres three miles from where my wife went to college.

This fortunately happened just before real estate prices escalated dramatically. We also learned at that time that banks really don't want to talk to self-employed people. We moved in with great plans to add on to the house, which was rather small.

We did some master planning, cleared a field, planted a cover crop of buckwheat--the flowers of which were beautiful but smelled like cat piss at night.

This fortunately happened just before real estate prices escalated dramatically. We also learned at that time that banks really don't want to talk to self-employed people. We moved in with great plans to add on to the house, which was rather small.

We did some master planning, cleared a field, planted a cover crop of buckwheat--the flowers of which were beautiful but smelled like cat piss at night.

We built a barn with lumber from the local lumber mill and from the trees cleared off the the field, planted fruit trees, a lilac garden, a raspberry patch and a huge vegetable garden, planted hundreds of daffodils and built and a fern house. We dug a few vernal pools which proved to be a bit too vernal necessitating a joint compound bucket rescue mission every June to move eggs to a neighbors pond before ours dries up. And we built a trail network that connects to a trail network in the forests to the North of our property around South Pond in Marlboro.

We built a barn with lumber from the local lumber mill and from the trees cleared off the the field, planted fruit trees, a lilac garden, a raspberry patch and a huge vegetable garden, planted hundreds of daffodils and built and a fern house. We dug a few vernal pools which proved to be a bit too vernal necessitating a joint compound bucket rescue mission every June to move eggs to a neighbors pond before ours dries up. And we built a trail network that connects to a trail network in the forests to the North of our property around South Pond in Marlboro.

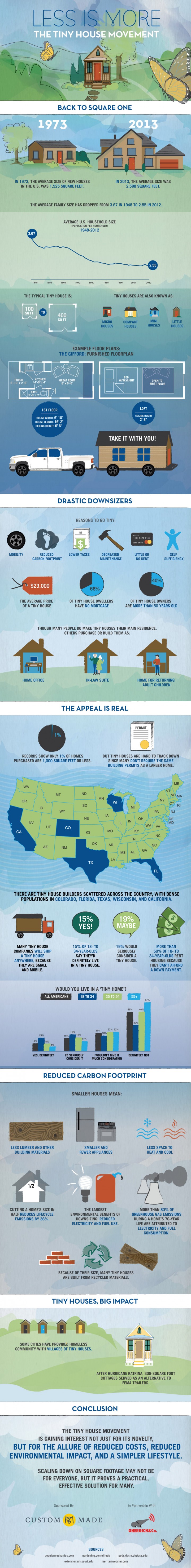

Our house, however remains at 900 square feet and remains relatively untouched . We still cook fabulous meals in the tiny kitchenette and heat the place with a wood stove tucked into the fireplace. I often work from home in the winter to keep the fire going. The bathroom desperately needs a gut remodel – a large section of tile fell off the wall a few years ago while I was taking a shower and I glued up some sheet metal “temporarily” and used some packing tape to reinforce the remaining tiles. Pitiful huh? Not an impressive home that I would want clients seeing. “Uh, yeah, that's the house..come see my cool modernist barn!”

My office was the second bedroom (9 ½ x 9 ½ feet square) until my daughter at age two announced that the room was now hers. (She needed a headquarters from which to plot her eventual world domination. And keep all her stuffed animals.) So I moved my practice into an office in Brattleboro's Cotton Mill where my wife works. This was a good move anyway as it gave me a place with high speed internet and a place to meet clients. Did I mention that dial-up is the only option on our rural dirt road? Previously, I had to go hang out at a cafe if I needed to download or upload large files, surf the web or meet with a client somewhere other than on site.

So my wife and I have this 4-year-old daughter who goes to preschool 5 days a week for some part of each day. We also have a beloved dog with DM (Degenerative Myelopathy) who needs someone with him most of the time in case he falls and gets stuck or poops himself. He got stuck under the Christmas tree a few months ago and I came home from errands to find him looking rather miffed but being remarkably patient. We currently spend a fair amount of time schedule-juggling to determine who has the kid and/or dog. For the time being, travel is out of the question as is most visiting. “We brought the dog and he might poop on your living room carpet!”

My wife is self-employed as a massage therapist and I am self-employed as an architect. There are periodic issues relating to the idea that one of us should have a job with benefits that would cover the family, usually around tax time when we tally up what we earned and realize that one of us really should head down to Wal-Mart to pick up a job application. We each work about ¾ time and feel like we are right out straight all the time. My wife has specific appointments for her work while I am usually just trying to accomplish my work whenever I can get a chunk of time to focus. I have found that if I achieve the necessary level of focus, I can accomplish huge amounts of work in a relatively short period of time. If I can't enter that zone, it is a painful thing to try to work and I am better off doing something else useful like increasing the size of my woodpile or weeding the garden. This pattern of work is not very conducive to employment in a firm if I remember those days correctly. I remember working 5 hours and getting more done than anyone else in the office but getting in trouble for not looking busy the rest of the time. I also seem to accomplish great feats of design and detailing while walking in the woods, riding my bike, xc skiing and more consistently, in the early morning hours when I often lie in bed for an hour or two working out details or design issues that I couldn't seem to focus on during the previous day. I often work from home in the summer as well, at a desk out in the barn loft where I can listen to the birds singing, the kid playing in the garden with the sitter, enjoy the warm summer breezes and work with relatively little distraction. (Also the cotton mill office gets a bit hot.)

At this point in my career, I tend to attract the type of client who has big ideas and a not so big pocketbook. Therefore the bathroom doesn't get renovated and the house doesn't get added on to. Often, projects end before they have really started when early in schematic design we realize that the wants/needs list won't match up with the $$. I certainly could use an occasional high end residential project so the “cobbler's children could have shoes” however. This blog has increased my exposure to a level that has allowed me to remain in business when most local architects and designers seem to be unemployed. It has also been rather cathartic as a way of letting off steam...although I try not to get too grumbly. I originally started blogging as a way to complement my website which seemed rather static – just a portfolio. I really wanted to communicate more of who I am, how I work, what it is like to work with me, what my values are and to open a general window into the process as most people really have no idea what to expect when they pick up the phone to call an architect. The blog has been very successful at that and I actually have around 1000 subscribers now which puts a bit of pressure on me to come up with decent content. Such as this post. I hope.

As I think forward to what I want the business to become I reflect on a business plan I worked on with my wife a few years ago. It was helpful to inform me what path I didn't want to pursue: to grow the firm with employees that I would have to work full-time just to keep busy and employed. I started to explore what is happening in terms of a different business model based on collaboration. I also realized that the days of the small town architect that does everything are fading away. Everything requires specialized knowledge that one person or even one small firm can't provide. I realized that I had numerous contacts in larger and more specialized firms that were interested in pursuing local work outside the residential realm in a collaborative relationship with me. The internet has changed the nature of the architecture firm dramatically in more urban environments and we are starting to see it in more rural areas as well. My new business model is based on this idea . And it allows me to focus on my greatest strength--which is not marketing, schmoozing, management of employees, being a super-geek, but is simply ….Design.

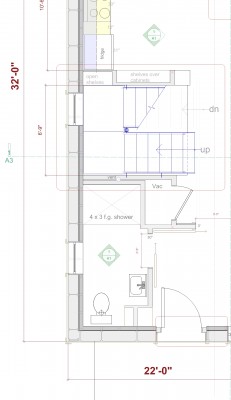

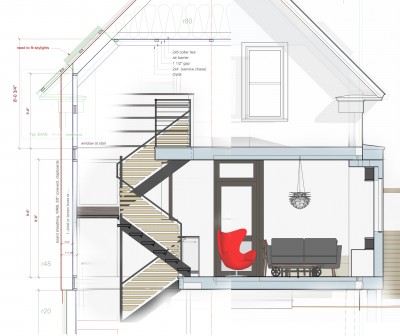

The stairs aren't in yet so I did some quick and dirty photoshopping:

The stairs aren't in yet so I did some quick and dirty photoshopping: