I have a lovely 30x40 barn that I built myself starting about a decade ago. This is one of those projects like architecture school that was a large undertaking of the sort that had I known....

We had just had a 1 1/2 acre field cleared as our property was all woods with the trees starting just a few feet from the house. The only way to see sky was too look up. straight up. It was very claustrophobic and we would walk over to the neighbor's field in the evening to see the sky and watch the sunset. The neighbor's father was a pilot many years ago and the field used to be used as an airstrip. So we needed a field of our own for garden, fruit trees and to play in.

Where we staked out our field was all forest leading up to a stone wall to the West, over which was a hay field. The trees that were cleared never left the property. We hired someone with a portable mill to slice them up into boards and leave them to dry. I still have a bunch of that wood and some recently made its way into the Greenfield house.

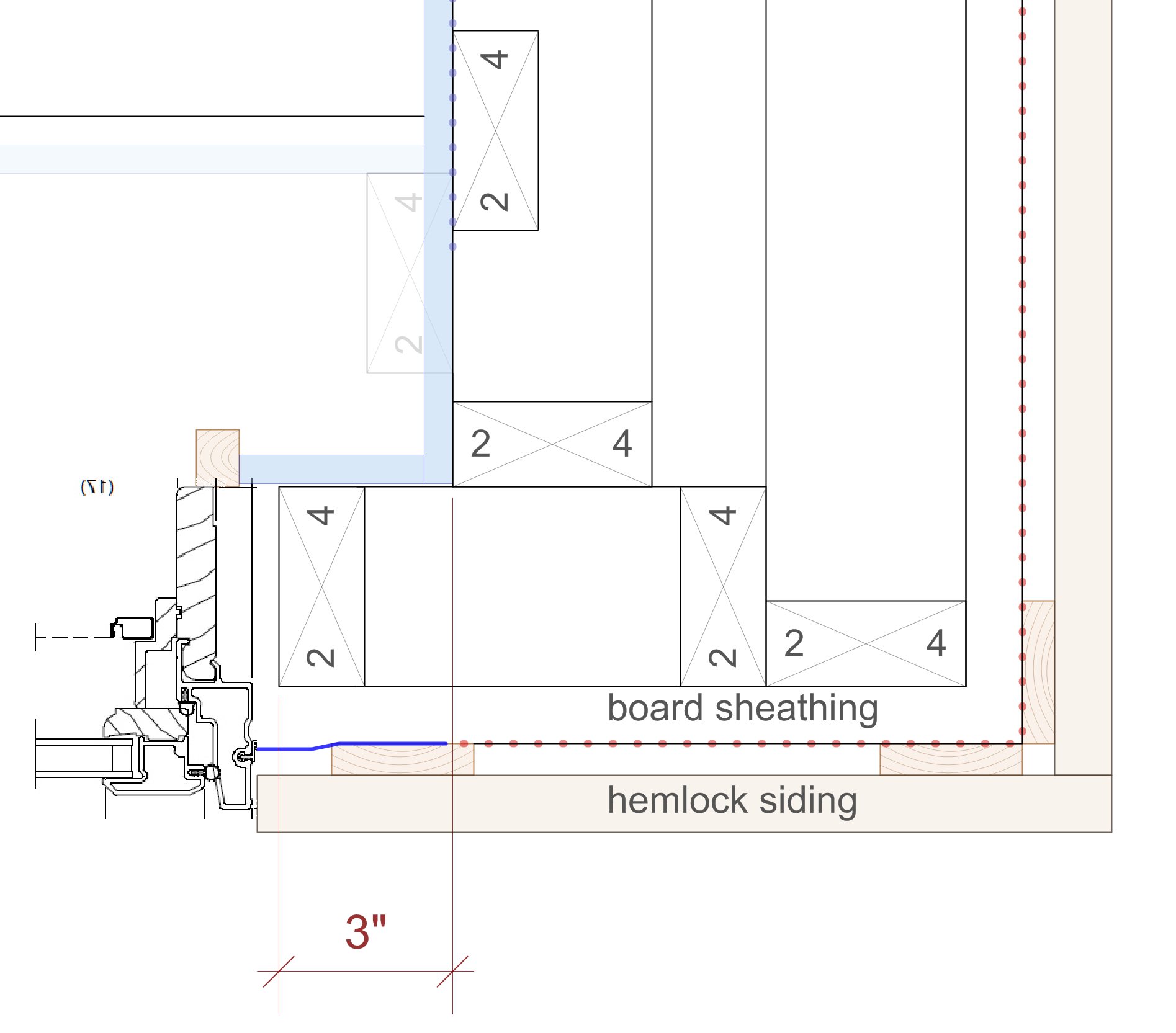

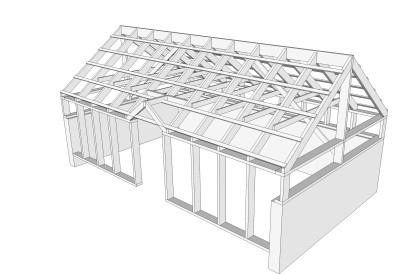

Much of the wood went to siding my barn. Some of the pine was made into very long 6x6 uprights which formed the pole grid for my barn. I used native green (not kiln dried) hemlock from a local mill for the rest of the framing, joists, rafters etc.

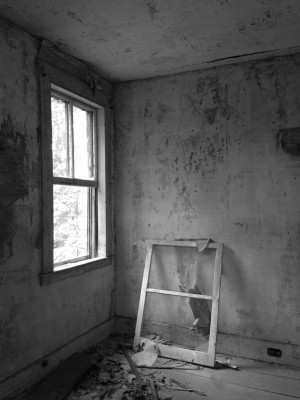

I did most of the site work, concrete (including a very scary one-piece retaining wall concrete pour complete with bulge) and initial framing of the upright 6x6 posts in 2006 and I managed to complete most of the frame and much of the siding the year after. I had some help with the first part of the roofing and the roof trim. Which was very very high off the ground. The end windows are old and very large sash that came out of the Cotton Mill in Brattleboro where I have an office. The side windows are old Andersons which came out of a building I helped deconstruct. The cupola and bike room utilize a greenhouse fabric that lets light in and has held up perfectly over the past nine years

What follows is a collection of newer pictures of the barn which turned out to be quite an amazing building. The acoustics of the loft are perfect and the lighting is divine. I am not finished yet - I still need a floor in most of the ground floor and I need to build barn doors.

In the summer of 2016 I built a new greenhouse and chicken coop between the barn and the house

The bike room in the barn - also a library - For bike geeks there is a 2013 Kona Jake the Snake, a 1981 Peugeot PXN10, a 2001 Klein Attitude race, a 1996 Marinoni with Dura Ace (17 lb build), a 1993 Cannondale M700, a 1987 Vitus 979 frameset, assorted wheels, panniers, kids bikes and old parts.

The Barn along with the Fern House made it into this book a few years ago We use the loft of the barn as a play space. It's also a good place to spread out some drawings to go over. We have a bed up there for guests and occasionally we will set up one or more tents for guests as well. I have some gym equipment in one corner and an old oak desk in another. The ground level has the bike room / library and a storage room which still needs a wall. I have much lumber stored in the main space plus my table saw and compound miter saw. two canoes, old tires.....

The stairs aren't in yet so I did some quick and dirty photoshopping:

The stairs aren't in yet so I did some quick and dirty photoshopping: