I helped out a bit with the design of a small timber frame home recently and I stopped by the job site when the cast and crew from Vermont Natural Homes were raising and assembling the frame with the help of a crane.

High Performance, Timber Frame House in Vermont

Last week I received these photos of a project I helped out with last year. When I say helped out it really means just that. As an architect, I do very little imposing on clients. I nudge, hint, suggest, recommend, advise but in the end it is their project and their money and people hire me for different reasons. Sometimes it doesn’t go as smoothly as this which ended up being a pretty sweet project and people make some really awful decisions. (you don’t see those projects in my portfolio but all architects have them) These clients live a few hours away in another part of Vermont. I visited them last spring and I’ll make sure to visit again.

Of all the projects I do, most projects involve some level of client involvement during construction – not just during the design phase. It may be as little as purchasing fixtures and lights and doing some painting but often I design for clients who will be doing the contracting and much of the building themselves. This is Vermont after all. It’s how we roll up here. In this case the young couple had family with timber framing experience, they had survived the house building process as kids and they were ripe for some professional assistance with floor plans, aesthetics and some good solid building science. The result is one of my favorite combinations – good building science, natural building and classical New England detailing and form. And enthusiasm.

Specifics:This is a timber frame cut from wood harvested on site. The frame is wrapped with a neat double stud detail that puts the intello air barrier in a nicely protected location. Braces are set so that sheetrock can slip nicely behind them saving much labor fussing. Much of the framing lumber also came from the site. Interior finishes are plaster which saved them money on taping and finishing the sheetrock as they were able to do it themselves. Future provisions were made for a mudroom and porches. This house may even end up being net zero. The overall footprint is 22’ x 34’ which seems to be a common size for my work in recent years. I can do a lot with that footprint. Enjoy.

This project represents a "limited services" project. My role is to assist where needed but I don't do full architectural services. My usual role involves lots of help with plans, advice with the building science and buildability aspects of things and helping the clients to keep things as simple as possible. I spend much time as a sounding board. Drawings are fairly minimal and often involves sketchup models and sketches in lieu of construction drawings. I do minimal structural and framing plans, no electrical plans, no interior elevations, minimal specs and schedules etc. We really focus on the core elements of the house. Costs for this level of service range between 2 and 5 % of construction cost if you want to look at it that way. I've done a lot of these projects over the years and I've been involved with some really great clients.

foursevenfive.com Feature - Greenfield House

The folks over at 475 High Performance Building Supply wrote a very nice article about the Greenfield house last week. foursevenfive.com provides building materials and expertise to many high performance home builders and architects.This plan will be the next stock plan available in the VSH - Vermont Simple House series. I'm working on bringing it to a high level of detail now.

The article contains many process photos and an excellent description of the process with Vermont Natural Homes, Helm construction Solutions and Deap Energy group

Greenfield House Complete

Here are some decent shots of the Greenfield House project which is nearly complete and not a full-on Passive house but did meet the Mass Tier 3 rating requirements. There will be minor things to do over the next year. I will continue to photograph this house over time to improve my photography skills so stay tuned for more. This project was a collaboration with myself, Vermont Architect Robert Swinburne, sometimes known as Bluetime Collaborative and Vermont Natural Homes and Helm Construction Solutions working for VNH Details: The house has 16" thick walls with an empty service cavity so that's not all insulation, Klearwall windows + a Menk storefront window, custom fabricated steel stairs with live edge cherry treads, local maple floors, Vermont slate tile in the upstairs bath and mudroom, stone countertops from Ashfield stone - (the stone is quarried locally and represents the underlying bedrock in this region) - accurately detailed and proportioned roof trim (to make the house look super classy) a bold front porch made from Vermont white cedar, black three tab shingles ( I HATE architectural shingles). We achieved an airtightness level of .066 - Mike Duclos of DEAP Energy Group did the testing and Mass Tier III certification. Fresh air is supplied by two pair of Lunos through the wall air exchange units from 475 High Performance Building Supply The overall footprint is 700 s.f. with 600 s.f. per floor on the inside. Visitors report that it feels much larger.

The overall design is intended to be super classy and appeal to both traditionalists and modernists without being overtly stylistically categorizable. I wanted to show that a modern, superinsulated (almost Passive House certifiable) house doesn't have to look super modern or look like it was designed by an person who only cared about the numbers like so many super high performance houses do. I think we pulled that one off.

Greenfield project update

I have a lot of photos from the Greenfield project. I am spending a fair amount of time on site working out details with the builder. I strongly feel that this is the way it should be. Things never translate perfectly from paper to built form no matter how much detail and specificity I put into a set of construction documents and on this project, I am spending much time on site figuring things out and detailing to a higher level. I think Chad, the builder, appreciates this process and I'm finding that it hearkens back to my pre-architect design build days. I hope to do more projects with this level of involvement in the future. I really think that this is "the way to go" here are lots of photos. Note the local wood use: Cherry stair treads with "live" edge, local maple flooring downstairs and pine upstairs, Vermont slate, and a wall sheathed with weathered pine off my own land.

Greenfield House project update

I spent part of Sunday painting at the Greenfield project with the builder Chad of Vermont Natural Homes. The all white primer that drywallers left us with was rather intense in the bright winter sun. The main bedroom upstairs which faces south was almost too bright to tolerate. It was good to spend much of the day there on a sunny day to better understand the light and to see how things will photograph when all is said and done. The color we used is a light blueish gray and it really had a soothing effect on the main room. I hope it will feel warm at night under artificial light as well. I am a bit concerned about this room as it had so much going on in terms of different materials on different surfaces. It was nice to spend the day talking with Chad about design and business and such. I don’t often get to interact on that level with the builders. There is a lot going on in this house that will help me learn and get better as an architect and help Chad get better as a builder. Plus the part where it is shaping up to be stunningly beautiful.

We tried a different construction method for this project than plain old double stud walls. There is potential in this method – (see previous post) but I don’t think we gained as much as we hoped in terms of air tightness and ease of construction. There are some Passive House builders using this method to hit ridiculously low cost per square foot numbers and it has numerous other advantages. I look forward to improving the detailing next time around. Double stud construction (used on the Ames Hill Project shown below) is the local standard here in Southeastern Vermont. The cost/benefit ratio is very high and local “green” builders are very familiar with it and prefer to build this way. Some local builders are also starting to advocate using locally milled boards as sheathing rather than OSB and plywood as well. I asked around (sent out a formal questionnaire even) and most think the cost difference is negligible.

We also had issues with the trusses on the Greenfield project. Maybe we just had bad luck but it seems that whenever I’ve tried to specify trusses to save money, they come through just imperfect enough to cause problems that need to be solved in the field.

I detailed lots of things both interior and exterior in such a way that they can be filled in later but don’t interfere with occupancy permit and impression of completeness. The sheetrock around the deep set windows for instance, costs more on the drywaller’s bill but when they leave, the window is essentially trimmed out. Done. We can add a sill later. Perhaps even just laying some slate tiles on the window sill. I have found that using wood trim on deep windows looks too...heavy and complicated. There are more cool and experimental things happening at this project as well which I will detail in a later blog post as they happen.

The stairs aren't in yet so I did some quick and dirty photoshopping:

The stairs aren't in yet so I did some quick and dirty photoshopping:

On most (all?) projects there is a level of design that is in the earlier, preconstruction drawings and models that I find really hard to convey to builders and clients and thus gets edited out of the final constructed project. Things that often look unnecessary on paper and I sound silly trying to explain but, the older and more experienced I get, the more I understand how important these things are. Once in a while I have a client who trusts me enough to let me do what I do to a greater extent. I suspect I have been luckier than most architects in that regard. I am so often trying to use space, light (and dark), flow, texture, detail, color etc. to shape and affect emotion and state of mind for my clients and I hope that long after I’m gone that will be a big and recognized part of my legacy.

This project and the Ames Hill Project have been opportunities to work with - and see how to work with - a full-on construction management firm – Helm Construction Solutions. This is part of trying to reach a higher level of service as an architect (it’s a hard thing to do as a sole proprietor) as well as re-write how projects happen locally. I have lots of cost and pricing information gathered on my own over the years that I can use for rough estimating purposes but what Helm does involves knowing the cost of things much more accurately earlier in the process. I have found few builders who can really do this well. It tends to be a level of service one would expect of a larger firm with a dedicated staff (back at the office) for this aspect of construction. It’s very much about managing expectations, communications, process, accountability and smoothing the tumultuous process of building as much as possible.

I filled out some of the Bluetime Collaborative section of my website finally – check it out from the top menu.

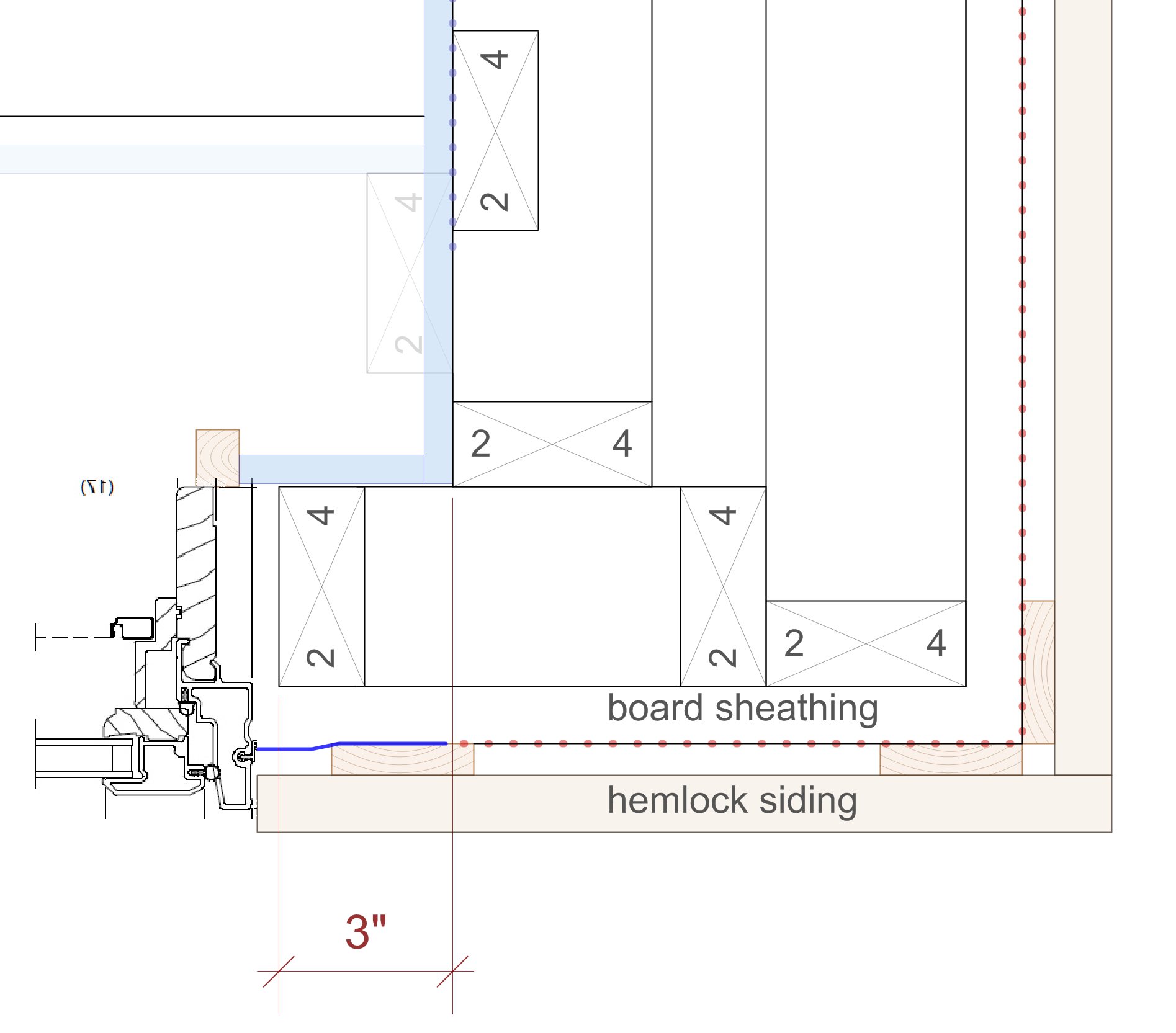

Hemlock - Open Gap Rain Screen Siding

My use of eastern hemlock as a siding material has been generating interest. Hemlock is a common wood in Vermont but doesn’t get used a lot except in barns and outbuildings and sometimes for timber frames. My summer job during high school involved working in a small sawmill. We sometimes cut hemlock and I found the wood beautiful, but heavy. One summer, we cut some hemlock for a bridge. Fast forward um… lots of years and I ordered a bunch of hemlock for framing and decking when I built my barn. I learned a bit about how to work with hemlock, how it ages and weathers and I started thinking about how I could use it in my own work. I try to source materials as locally as possible and design within local builder's abilities and interests - which is easy to do here where builders get together monthly to discuss building science related issues

In rural New England, buildings are often sided with pine siding in a vertical shiplap form – and often unfinished. It tends to develop a black mold that is relatively harmless but can be ugly. I found that hemlock is more resistant to this mold. It’s also harder and more rot resistant. It is nowhere near as rot resistant as cedar, a more common siding material however.

White pine siding on my own barn

A brief on open rainscreen siding: Good architect and builders are installing siding with a vented airspace between the siding and weather resistant barrier (WRB). This allows any moisture that gets behind the siding to dry out before it does damage. Modern materials (a better WRB) and the venting detail allow us to use different materials and different details for the siding itself. I have commonly seen the open gapped rainscreen detail used with ipe boards but Ipe is a tropical hardwood related to mahogany. Cement based boards are also used commonly but cement has fairly high embodied energy. Both of these are not locally sourced materials. The gap in the siding also reveals a view of the WRB (depending on the size of the gap) This means that damaging UV rays are also reaching the WRB. And bugs. Thus the need for a better (and black) WRB. There are several on the market designed for this. Both projects shown here use Mento and tapes from Foursevenfive.com

It occurred to me that I could use narrow hemlock boards from local mills to create a very elegant (I hoped) rainscreen siding detail. It would use local and relatively inexpensive materials, it wouldn’t need paint or stain, installation could be simpler and faster if I got the details right, and if I installed it horizontally, the lowest courses could easily be replaced if the siding degraded due to splashback and snow banks. The damaged siding would not present a disposal concern – just toss it in the bushes and it becomes habitat for red backed salamanders. I was lucky to have a client with a taste for modernism allow me to try my ideas out on his home. The results were rather spectacular and gave me a sense of the potential. Now I am doing my second project with hemlock siding. The builders for this project (Webster Construction of Marlboro, Vermont) are quite familiar with good building science and modern products and methods. They saw the potential and were happy to give it a try plus they were able to improve my detailing in several ways which I can then incorporate into drawings and specifications for the next time around.

The hemlock turns silvery gray within a year. The narrow boards create a woven, fabric-like aesthetic.

The hemlock is installed "green" with deck screws. This siding is all 1x3 so gaps will be quite small as the wood dries. Fiberglass bugscreen is installed directly behind the siding. strapping can be regular 1x3 strapping although coravent makes an excellent product for this purpose and should at least be used on any strapping set horizontally such as over and under windows.

This is the corner trim detail the builder came up with and I really like. One side runs long and is cut after installation. The other side is held back for a crisp reveal - very architecty! Of note: the deck is white oak (local) and the post is European Larch which is from a harvest of a Vermont tree farm. European larch is used in Europe as a durable siding material that needs no treatment.

detailing around windows is super simple. On the first house I used metal panels (installed by the roofer) to accentuate the windows and wrap corners. Here it is about as simple as it gets.

House size and ruminations Thereupon.

I am fascinated with the Tiny House Movement. Tiny House on Wheels is THOW btw. I would like to have one as guest quarters (or an airstream) but after living in a smallish (900 s.f.) house for 15 years I know that a tiny house is not for me. I do have plans to add several hundred square feet in the form of a functioning kitchen, eating area, mudroom, and a work area so I can ditch the in-town office. A THOW would have been perfect when I was young and single. I actually lived in an 8x12 cabin in the woods for 6 months sometime in the 90’s. Other than the mice and raiding raccoons, it wasn’t bad. I moved out when I started getting cold in late fall. -Pictured above Kids take up a lot of room and in our climate, you can’t just kick them outdoors to ride their bikes or do huge art or building projects. Plus each kid has to have two snowsuits, multiple winter boots, sleds, tons of books, a guinea pig (my daughter wants a cow and chickens) Not very applicable to tiny house living. Check out my friend Sean’s tiny house related blog UnBoxed House. He is building his own house using a shipping container. Although I have done a few tiny houses for clients I find I have to keep the tiny house mentality out of my regular work and attitudes, at least for now. I have found that some people are Big House People and a few (very few) are small house people. The usual conundrum comes when people have tiny house budgets but are horrified when I suggest that they need to be looking at something smaller than 1500 s.f. given their budget and their desire for quality. I once had a client who was horrified and outraged that I had designed a house with 10x12 bedrooms for her boys. (her budget was 350k) (plus she wanted a garage) Where I grew up that was a big enough bedroom for 2 boys to share. I will push and nudge and suggest like crazy but some people are just “Big House People” I have a hard time relating sometimes but I try. I nod my head sympathetically when a clients who are expecting their first child and live in a house twice the size of my own have called me in to discuss an addition to accommodate their growing family. Fine if they can afford it. I know from experience that I feel strangely uncomfortable in a house bigger than 2000 s.f. It feels wrong. Likewise a big bedroom. I contribute that to my introvert nature more than anything. I must be a medium house person. I follow a few tiny house groups on Facebook but try to ignore them mostly as people put up photos of their tiny houses that they built that, as an experienced architect, I can see that in five years, the house will be a falling apart mold factory. My face hurts too much from that sort of thing. But I applaud the do-it-yourself nature of the movement and the growing wealth of information and support.

Greenfield House - client perspective - mid design

Bob, in response to your invitation to comment on the passive house you are designing for us, here are some thoughts. I see this first of all as an opportunity to be part of the solution instead of part of the problem. The chance to show off the kind of technology and design choices that--were they widely adopted--could significantly reduce reliance on fossil fuels feels not just like an opportunity to showcase your talents as an architect but to participate in a necessary new way of thinking about housing. That you are, coincidentally, our son-in-law certainly plays a role in our enthusiasm, but it goes so far beyond providing for immediate family and grandchildren. It goes to realizing the models that are going to keep the earth inhabitable for everyone's grandchildren.

Coming back to the ground now, to the very immediate house in question and the very personal responses on an aesthetic and emotional level: It's exciting to think about having a space designed to support who we are and how we like to occupy space. The openness of most of the design, combined with the privacy of spaces designated for bedroom and in-home offices for each of us, is perfect. I imagine fondly the day when, if one of us is cooking in the kitchen and the other is in the living room, we won't have to shout to each other to be heard. I look forward to having a cup of tea by the floor-to-ceiling south-facing windows. Visual access to the outside year-round is crucial to my mental health, and if I have a view of the outside space, I need far less inside space. I am inordinately pleased by the idea that we may be able to design a root cellar into this house. The idea of storing garden vegetables connects the seasons for me. (An aside: I got a ridiculous amount of pleasure in Seattle from picking kiwi fruit in October/November, and eating it in December, January, and even February.) And, of course, those floor-to-ceiling south-facing windows will be a great spot for starting plants in the winter and early spring. Did I say I love the idea of floor-to-ceiling south-facing windows?

We love wood fires, but I've got to admit that each time I build one these days and notice the ash that has to be cleaned out and the wood dust on the rug that will need to be vacuumed I realize these are tasks I will not miss. And again, as we age, and things tend to take a little more time to accomplish just because of increased physical limitations, I won't regret leaving wood and ash hauling behind. It will leave more time for reading and writing. In the cozy office spaces or by the wonderful floor-to-ceiling windows.

Then there’s air quality and noise issues. I’m given to respiratory irritations and ailments, which means that, especially during heating season, I keep a HEPA filter running in the living room and a humidifier in the bedroom. Both are noisy, but help to create a white noise effect that drowns out traffic on the street outside. I know I’m going to enjoy the quiet of a super-insulated house and the climate-controlled clean air I’ll be breathing.

As we are very near retirement age, it pleases me that we're designing this house to be one in which we can age. Thinking ahead not to the inevitability but the possibility of one or the other of us needing a wheelchair at some point, and having the first floor bathroom at the ready, means not having to worry about retrofitting in a hurry someday.

Just knowing some of the principles of Passive House design has made me so much more aware of heat and cold. I take a hot bath, and imagine the system that will capture the heat as the water cools. I open the curtains when the sun is shining, the better to capture a bit of the free solar warmth. I have begun to use the term "thermal bridging" in casual conversation.

Circling back to the overview: I like that we are able to support, with this project, not only the concept of Passive House but also the business model that you, Mel, and Chad are using. Having presided over a remodel in Seattle, I need no convincing that it's going to be worth it to have project coordination and scheduling built in to the process and the services your team is going to provide us.

Early Thoughts on the Greenfield Project (architect)

I took a shot at writing down my own thoughts about the Greenfield project I’m doing for my wife’s folks. Sometimes I have so many half-baked ideas in my head that writing them down creates a jelling effect and helps me to clarify and focus my efforts. I’m planning on documenting this project to a much higher level than I have in the past, partly because we are assembling something of a dream team to get this done and partly because I am using this project to redefine how I work in order to bring my own practice to a higher level. I have encouraged the others to start writing as well and some of that will show up here on the blog as well for a more well-rounded perspective. We are currently exploring the feasibility of doing this house as a Passive house and seeking certification. I hope, as usual, to show what can be accomplished when a highly functional and customized plan is also an emotionally uplifting place to live. This projects continues my exploration into the emotional aspects of “home” and how to use architecture to augment and reinforce the emotional connection to place. Phew! What have I to gain from doing this project as a full-on Certified Passive House? So what if the winter heating bills drop from $75/month to $25/month? Is that really worth all the extra effort and expense to go through certification? We don’t know the answer to that yet. “Let me run some numbers” as the engineer or accountant would say. Passive house has cache. It attracts media. There is huge marketing potential. The clients (my in-laws) are understandably interested in that aspect of it - it relates to their son-in-law’s ability to financially support his wife and children. I want to do more of this type of work in the future and will I ever get such a good opportunity to gain exposure, attention and build a reputation that to do a very attractive and relevant project at this highest level… and market it to the greatest extent possible. I have seen that model propel other firms into the limelight so I am aware of what power and potential in inherent in this thinking. Otherwise- My own limited knowledge of Passive House indicated that this house as designed thus far could attain Passive House certification with minimal extra effort. I’m a Certified Passive House Designer – CPHD with the international credential but I have little practical experience. This project could be a great way to gain that experience. The most effort and extra money will probably be in soft costs – hiring someone with experience to do the energy modeling, advise on detailing and assist in the certification process. With this project we are also formalizing a fairly progressive project delivery process that I am realizing is crucial to creating high performance buildings. This represents the direction my own business model is headed in. I have, in the past, followed both the more traditional architect route where I work with clients to design and detail a project and we shop it out to builders. I have also worked (more often) in a more design-build model where the builder is integrated into the process from very early in the process. That has been my preferred method of project delivery but I am realizing that to provide the highest levels of service, I need to fill in some gaps. I can’t do everything and I don’t have expertise in everything so I’m bringing in people to help fill the traditional gaps. Subcontractors as well need to be on board as part of the team at a much earlier stage and need to be aware that they will be asked to perform at a very high level of professionalism. Part of my job is to make that as easy as possible for them through design and detailing. I am working on this project with Mel Baiser of Baiser Construction Management and Chad Mathrani of Vermont Natural Homes both of whom have training in passive house detailing and construction. They understand what it takes to reach that highest level of building excellence. And considerable enthusiasm to do so. We are pouring over the details as fast as I can draw them up to insure that no stone is left unturned. The process requires a high level of integration at this early stage in terms of product selection, integrated assembly, cost (and relative costs). Assumptions are challenged and vetted and everything will be put down on paper before the project is staked out on the site which is under considerable snow at the moment. We will maintain a process blog as part of Vermont Architect to provide a window into this process. Blog readers and Bluetime Collaborative facebook followers have already seen some early schematic design images of this project. Stay tuned.

A Smallish House in Massachusetts

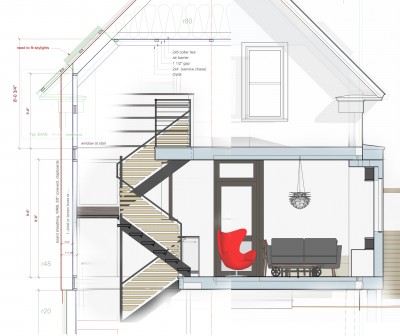

I am working on a 1400 s.f house in Massachusetts. Given that the walls are over a foot thick, the actual square footage is quite a bit less (about 1200). The extra insulation (and cutting edge building science) allows us to forgo a heat system other than a relatively inexpensive minisplit - and monthly fuel bills. Here are a few images of what I'm up to. no fancy rendering for now, just the Sketchup model and some Vectorworks CAD drawings.

I spent a fair amount of time detailing the steel and wood stairs in Sketchup as I have found that is the only way for me to really figure out every nut and bolt and refine the design to the level that I am comfortable with before construction drawings. I like to approach the stair as sculpture with every piece exact and connections "just so". Thus I am able to design something that is quick and easy to assemble with just the right amount of "fudge space" built in.

The floor plans have shrunk and simplified from the last version becoming more functional and comfortable.